2101510 Rev. AG

Page 3–25

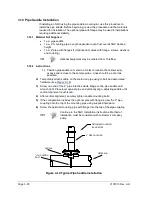

9)

Insert the ferrule into the sample conditioning module input fitting. Move the nut

down onto the ferrule, screw onto fitting and tighten.

10)

Locate the sample output fitting on the sample conditioning module.

11)

Locate the sample input on the NGC feed-through assembly and remove the

sealing screw.

Leave the sealing screw in any unused ports. If unused

stream ports are not sealed, moisture can enter the manifold

which can damage the instrument and void warranty.

12)

Make the necessary bends in the tubing to ease installation of the tubing into the

output fitting on the sample conditioning module and the ferrule and Valco nut

into the input on the NGC feed-through assembly.

13)

Insert the tubing with the ferrule into the output fitting on the sample conditioning

module. Move the nut down onto the ferrule, screw onto fitting and tighten.

14)

Remove the plastic caps from the restrictor coils, the sealing screws from the

feed-through column vents and the sealing screw from the sample vent lines.

15)

Purge the air from the transport tubing by opening the shut-off valve located on

the sample probe.

Be sure to follow requirements of national and local codes

when performing this purge.

16)

Insert the tubing with the ferrule into the corresponding input port located on the

NGC feed-through assembly. Move the Valco nut down onto the ferrule, screw

into port and tighten.

17)

Repeat for each sample stream.

Do not over-tighten. After securing tubing, check for gas

leaks.

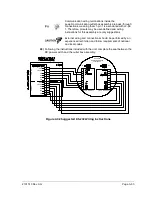

3.15 Sample Line(s) to NGC Inside of ENC82

Sample line(s) being installed to a unit located inside the

ENC82 require making minute changes to the instructions

listed for their installation. The following information and

steps should be noted during the installation.

3.15.1 Materials

•

Installed sample conditioning module for each stream.

•

1/8” SST chromatography grade transport tubing (amount to be determined by

technician based on distance from sample probe to sample conditioning module

and number of sample streams.

•

2 ea. ferrule and nut (for each sample stream)

•

1 ea. ¼” NPT to 1/8” reducer or other size as determined from sample probe

output port (for each sample stream)

•

1 ea. sample conditioning module transport tubing (supplied with sample

conditioning module).

•

1/16” or larger vent tubing and materials for making connection to 1/16” purge

coil to vent outside of enclosure (provided by customer for each stream)

•

Heat trace materials provided by customer for each stream