641P026-008

HMB-8 / HMB-8.7 Mechanism

©

(formerly HMB-11)

Page 7

4 November 2005

3

Principles of Operation

The HMB-8 mechanism uses the principles of hydraulics

to compress and charge the disc spring assembly. Hy-

draulic oil is transferred from a low pressure reservoir

97605 (Fig. 1) to a high pressure reservoir by a pump motor

51002 (Fig. 1) and pump element 51014. The high pres-

sure oil is used to compress the disc spring assembly with

the accumulator pistons. The disc spring assembly 51008

(Fig.1) acts as an energy storage system. During breaker

operation, stored energy is consumed and the disc spring

assembly discharges accordingly. The pump motor limit

switch (Fig.4) actuates and the pump motor automatically

re-charges the disc spring assembly. Principles of the

OPEN and CLOSE operations are described in the follow-

ing sections:

• Section 3.1 CLOSE operation

• Section 3.2 OPEN operation

3.1

CLOSE Operation

The front side of the drive piston 51012 (Fig. 2) is always

under hydraulic pressure when the disc spring assembly

51008 is charged. In the OPEN position, the back side of

the drive piston is at low pressure.

On actuation of the close pilot valve 51004 (Fig. 2), the

changeover valve 51006 moves to the orientation shown in

the CLOSE position illustration of Figure 2 allowing high

pressure hydraulic oil to flow on the back side of the drive

piston. Although there is high pressure on the front side of

the drive piston, the drive piston travels in the CLOSE

direction because the surface area on the back side of the

drive piston is greater than the surface area on the front side

of the drive piston, creating a net force in the CLOSE

direction.

A low pressure interlock 51016 (Fig. 9) prevents the drive

piston 51012 (Fig. 2) from drifting into the OPEN direction

in the event of very low system pressure. This interlock is

provided when required by the breaker type.

3.2

OPEN Operation

On actuation of the open pilot valve(s) 51005 (Fig. 2), the

changeover valve 51006 moves to the orientation shown in

the OPEN position illustration of Figure 2. High pressure

hydraulic oil flows from the back side of the drive piston

51012 and is released into the low pressure reservoir

97605 (Fig.1). The constantly present high pressure oil on

the front side of the drive piston propels the piston into the

OPEN position.

3.3

Over-Pressure Relief Device

The HMB mechanism is equipped with a pressure relief

valve 51045A (Fig. 2) to prevent damage or catastrophic

failure of components due to over-pressurization. Should

an over-pressure hydraulic situation occur because of a

pump motor failing to stop, the pressure relief valve 51045A

(Fig. 2) will prevent damage by automatically releasing

high pressure oil into the low pressure reservoir 97605

(Fig.1).

4

Mechanism Maintenance

Major

maintenance involving disassembly of the HMB-8

mechanism can be performed by factory-trained represen-

tatives or by trained customer technicians. Major mainte-

nance is performed only if a problem arises.

To ensure proper operation, the HMB mechanism requires

routine

maintenance checks every year. Addtional mainte-

nance checks are required after every 5 years of service.

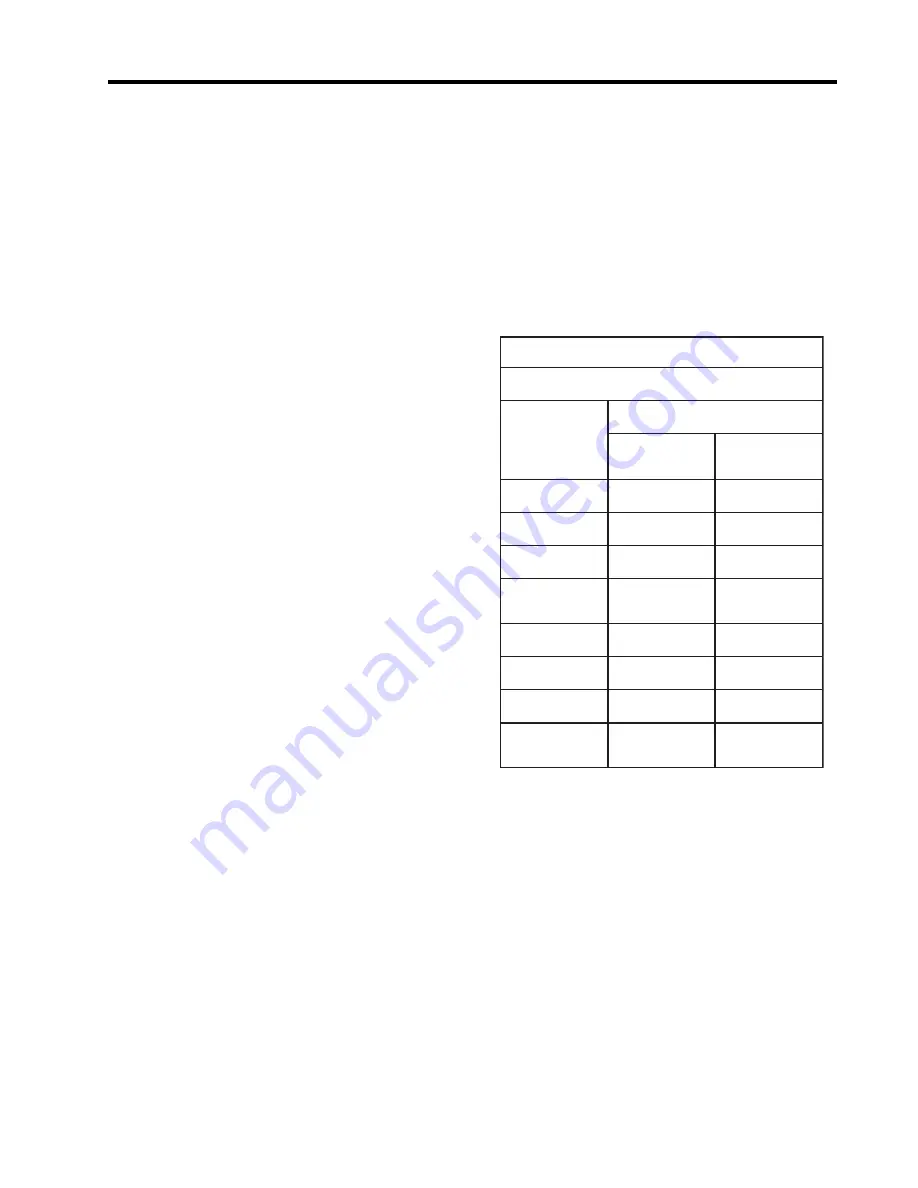

Table 1 lists a routine maintenance check schedule for the

HMB mechanism.

1

e

l

b

a

T

s

k

c

e

h

C

e

c

n

a

n

e

t

n

i

a

M

e

n

i

t

u

o

R

k

c

e

h

C

o

t

m

e

t

I

y

c

n

e

u

q

e

r

F

y

l

r

a

e

Y

y

r

e

v

E

s

r

a

e

Y

5

l

e

v

e

L

li

O

k

c

e

h

C

k

c

e

h

C

n

o

it

i

d

n

o

C

li

O

-

-

-

-

k

c

e

h

C

s

e

h

s

u

r

B

r

o

t

o

M

k

c

e

h

C

k

c

e

h

C

-

a

s

n

e

d

n

o

C

-

it

n

A

r

e

t

a

e

H

n

o

it

k

c

e

h

C

k

c

e

h

C

g

n

ir

i

W

-

-

-

-

k

c

e

h

C

s

l

a

n

i

m

r

e

T

-

-

-

-

k

c

e

h

C

r

e

t

n

u

o

C

t

r

a

t

S

k

c

e

h

C

k

c

e

h

C

e

r

a

w

d

r

a

H

s

s

e

n

e

t

h

g

i

T

-

-

-

-

k

c

e

h

C

DANGER

Mechanisms pose inherent hazards

associated with high energy equip-

ment having rapidly moving parts

and electrical components. Only

qualified personnel possessing a

full understanding of this equipment

should operate or service this equip-

ment. Be careful of limbs and ex-

tremities when working around this

equipment as they may become en-

tangled in moving parts.

Summary of Contents for Mechanism HMB-8

Page 2: ......

Page 5: ...641P026 008 HMB 8 HMB 8 7 Mechanism formerly HMB 11 Page 5 4 November 2005 ...

Page 19: ...641P026 008 HMB 8 HMB 8 7 Mechanism formerly HMB 11 Page 19 4 November 2005 NOTES ...

Page 33: ...641P026 008 HMB 8 HMB 8 7 Mechanism formerly HMB 11 Page 33 4 November 2005 NOTES ...