27

15. Troubleshooting

This section mainly describes how to handle hardware errors. Refer to the configuration program’s on-

line help for errors related to the software.

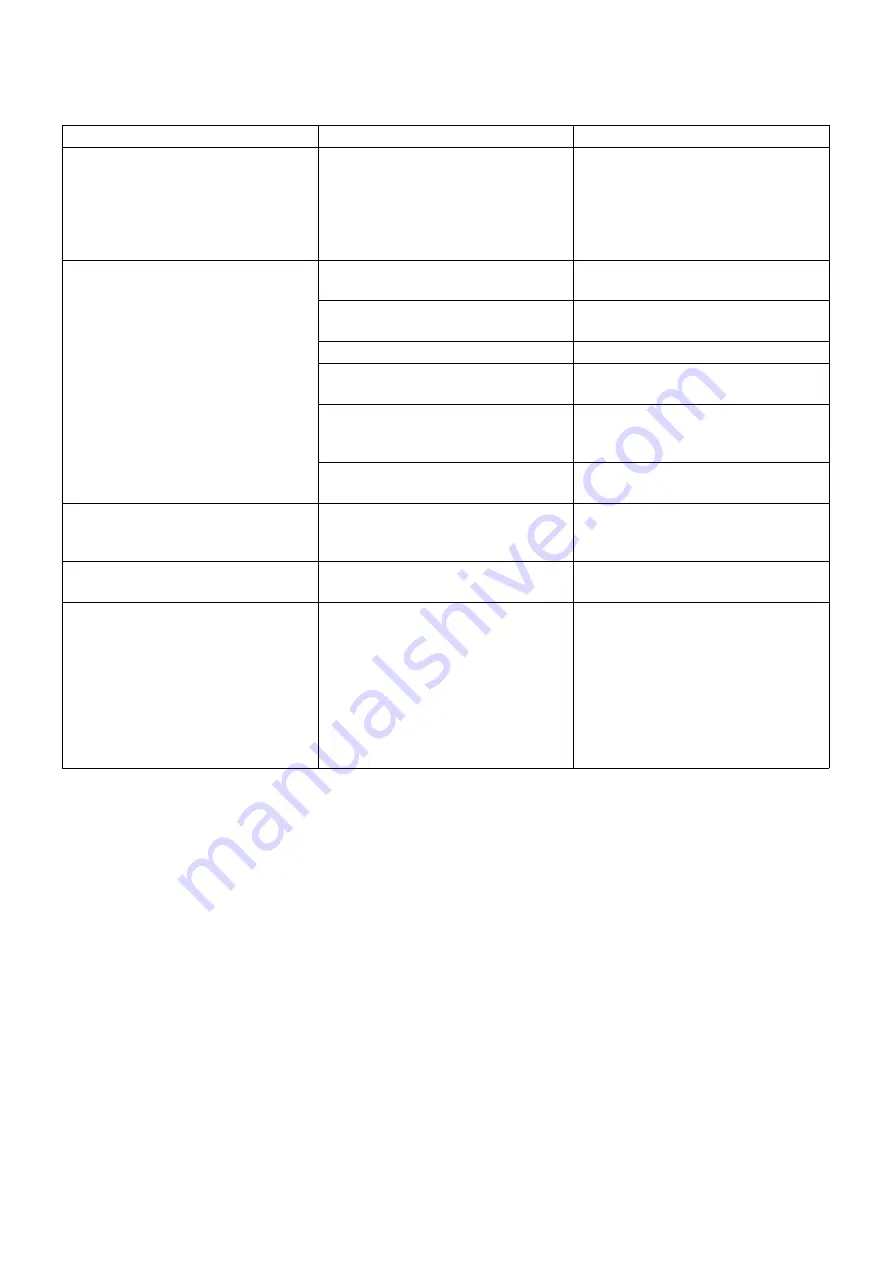

Table 8:

Error

Possible reason

Measures to be taken

Valve cannot be moved by actuator

Malfunction of actuator or valve (e.g.

stuffing box tightened too much)

Disconnect the actuator from the

valve.

If the actuator is working properly

then, the valve is likely to be defec-

tive. Otherwise, the actuator seems

to be the error source.

Actuator does not react

Wrong electronic unit or wrong data

Compare data lables of actuator and

electronic unit

Faulty electronic unit settings

Check / modify settings using the

configuration software

Faulty communication to DCS

Check wiring

Faulty wiring between the electronic

unit and the actuator

Check wiring

Motor / brake is defective

Check the winding resistances of the

motor and brake. Check the brake

fuse.

Digital inputs of electronic unit are

not connected

Connect

Actuator does not work in automatic

mode, although “AUT“ has been

selected in the configuration program

Digital input 1 (DI 1) has not been

connected.

-

Connect DI 1

-

Check software settings for digital

inputs

LEDs on the commissioning and ser-

vice field are flashing simultaneously

Actuator operating range has not

been adjusted properly

Adjust the actuator operating range

(see instruction for electronic unit).

Fault when approaching an end posi-

tion

Actuator is working in the limit range

of the position sensor

-

Move the actuator either manually

or with the LCP buttons to a posi-

tion beyond the end position (dis-

connect from valve if required).

-

Move actuator back. If required,

reconnect to to the valve (if appli-

cable)

-

Adapt actuator to new operating

range