ACH550-UH User’s Manual

235

Technical Data

Recommendation for Conductor Layout

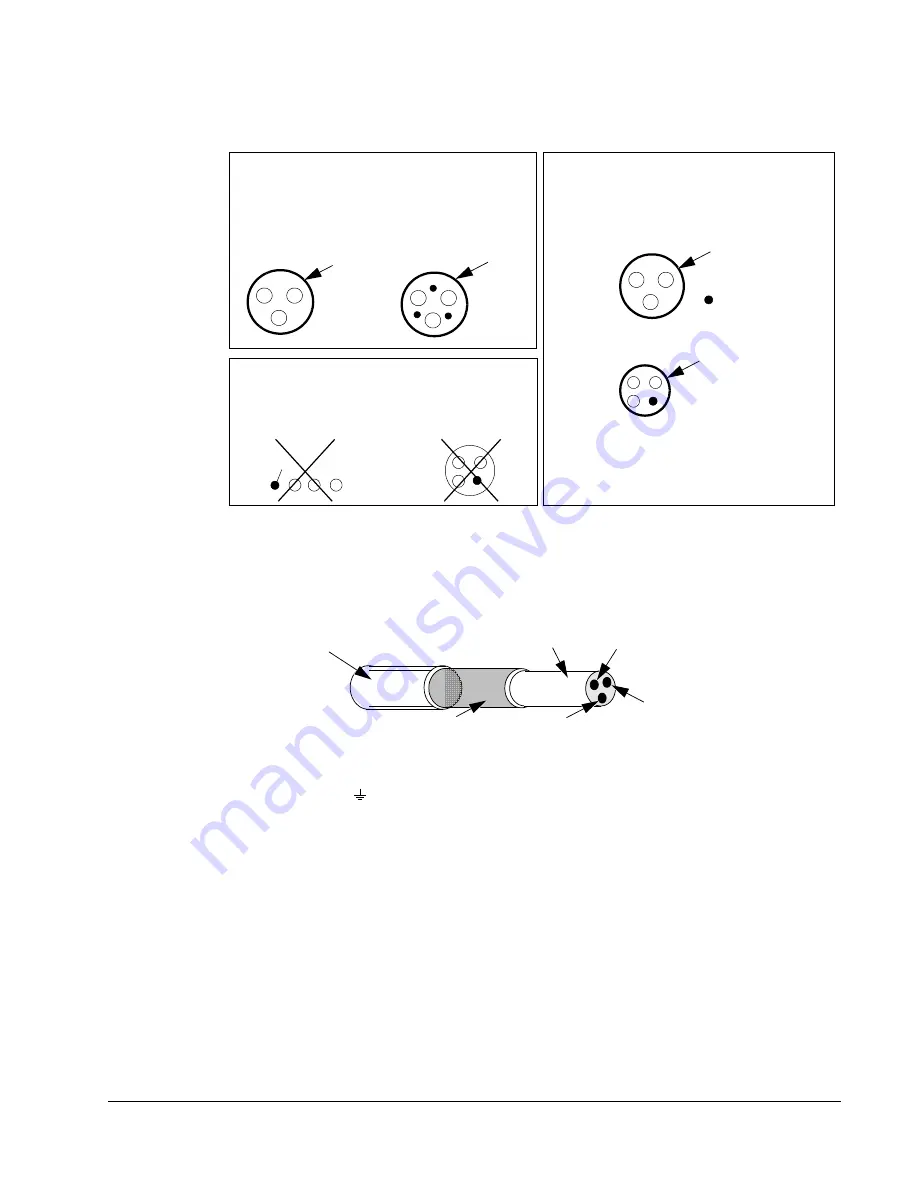

The following figure compares conductor layout features in motor cables.

Effective Motor Cable Screens

The general rule for cable screen effectiveness is: the better and tighter the cable’s

screen, the lower the radiated emission level. The following figure shows an

example of an effective construction (for example Ölflex-Servo-FD 780 CP,

Lappkabel or MCCMK, NK Cables).

Clamp the cable shield into the gland plate at the drive end. Twist the cable screen

wires together into a bundle not longer than five times its width and connect it to the

terminal marked

(at the bottom right-hand corner of the drive).

At the motor end the motor cable screen must be earthed 360 degrees with an EMC

cable gland or the screen wires must be twisted together into a bundle not longer

than five times its width and connected to the PE terminal of the motor.

EN61800-3 Compliant Motor Cables

To comply with EN61800-3, First and Second Environment (Restricted Distribution)

requirements, motor cables:

•

Less than or equal to 30 m (100 ft) do not require an RFI/EMC filter.

•

Must have an effective screen as described in "Effective Motor Cable Screens" on

page 235.

•

Must be earthed, at the motor end, with an EMC cable gland.The earthing must

contact the cable screen all the way around the cable.

Symmetrical shielded cable: three phase

conductors and a concentric or otherwise

symmetrically constructed PE conductor, and a

shield

Recommended

(CE & C-Tick)

PE

Conductor

and Shield

A separate PE conductor is required if the

conductivity of the cable shield is < 50% of the

conductivity of the phase conductor.

Not allowed for motor cables

(CE & C-Tick)

Shield

PE

PE

Allowed for motor cables

with phase

conductor cross section up to 10 mm

2

.

A four-conductor system: three phase

conductors and a protective conductor, without a

shield.

Allowed

(CE & C-Tick)

Shield

Shield

Insulation Jacket

Braided Metallic Screen

Inner Insulator

L1

L2

L3