6

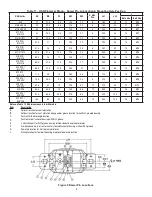

Table 7 - Viscosity of Oil in the Grease

DN

Viscosity for Loads Up

To 18% of Dyn. Cap*

(Cst @ Oper. Temp.)

DN

Viscosity for Loads Up

To 18% of Dyn. Cap*

(Cst @ Oper. Temp.)

2500

700

35000

125

5000

650

40000

100

7500

580

45000

85

10000

500

50000

75

12500

425

75000

62

15000

390

100000

42

17500

325

125000

30

20000

280

150000

27

22500

235

175000

22

25000

200

200000

20

DN = Bore Diameter (mm) x RPM

* = For loads above 18% of dynamic capacity an EP grease with the

above viscosity oil is recommended.

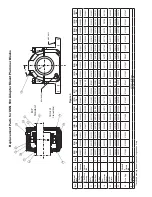

Table 8 - Regreasing Intervals (Months) *

(Based on 12 Hours Per Day - 66

° Max.)

Size,

mm

RPM*

250 500 750 1000 1250 1500 2000 2500 3000 3500

35-60

8

6

4

3

2

1

.5

.5

.25

.25

65

7

5

3

2

1

1

.5

.25

.25

70-85

6

4

3

2

1

.5

.25

.25

90-100

5

3

2

1

.5

.5

.25

110-130 4

3

2

1

.5

.25

140-160 3

2

1

.5

.25

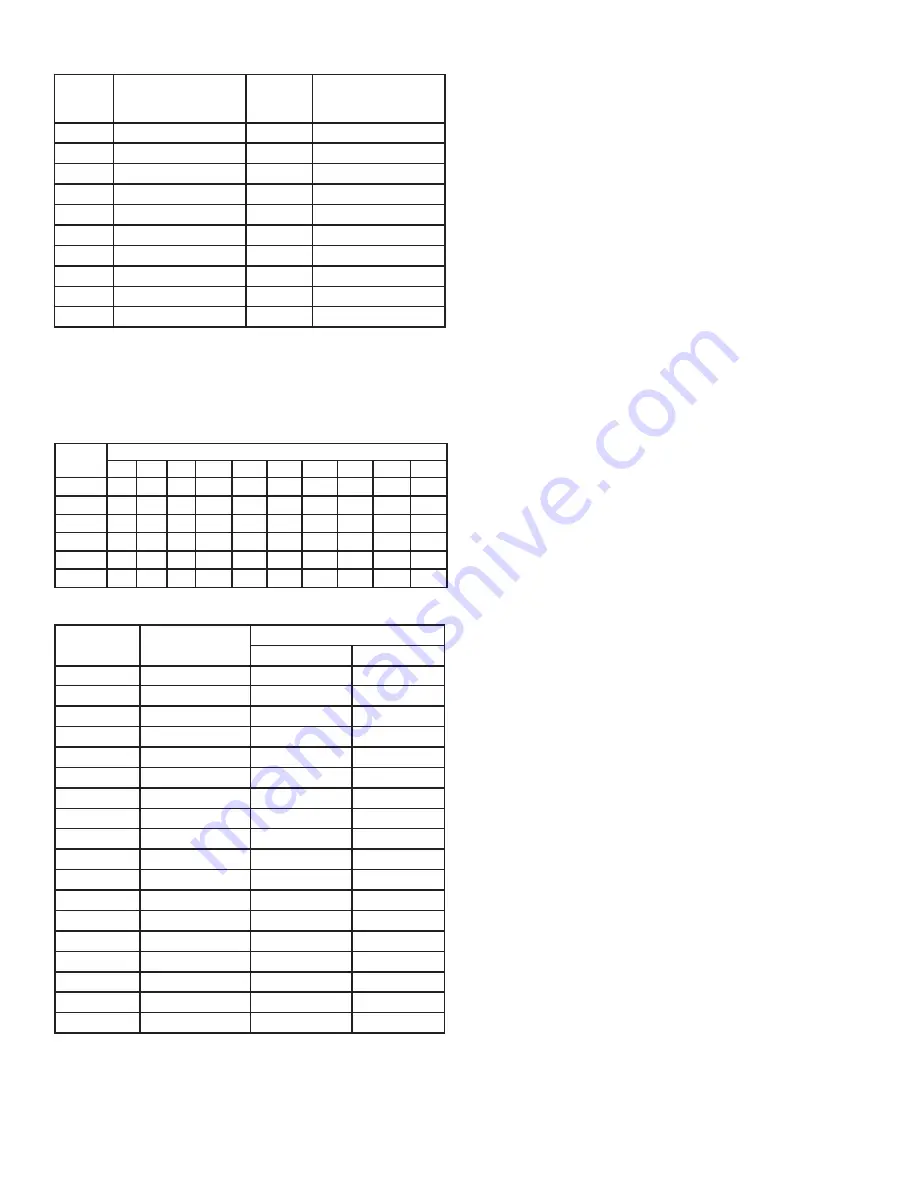

Table 9 - Maximum RPM (Adapter Mount)

Shaft Size,

mm

Basic Bearing

Description

Maximum RPM

Grease

Oil

35

22308K C3

4300

5300

40

22209K C3

5600

7000

45

22210K C3

5300

6700

50

22211K C3

4500

5600

55

22212K C3

4000

5000

60

22213K C3

3600

4500

65

22215K C3

3400

4300

70

22216K C3

3200

4000

75

22217K C3

3000

3800

80

22218K C3

2600

3400

85

22219K C3

2400

3200

90

22220K C3

2200

3000

100

22222K C3

2000

2800

110

22224K C3

1800

2400

115

22226K C3

1700

2200

125

22228K C3

1600

2000

135

22230K C3

1500

1900

140

22232K C3

1400

1800

If the RPM of the application falls between 20% and 80% of

maxiumum RPM (Table 9 for adapter mount, Table 10 for direct

mount), pack the lower half of the housing one-third to one-half

full. If the RPM of the application is less than 20% of maximum

RPM, pack bearing housing cavity 100% full. If the RPM

exceeds 80% of maximum RPM, do not add grease in the lower

half of the housing nor in the cap.

At each regreasing cycle, for applications up to 80% of

maximum RPM, slowly add grease until fresh grease is

seen purging at the seals. Regreasing should be done while

running. Remote re-greasing lines should be added to avoid

endangering personnel.

If the RPM is greater than 80% of maximum RPM, add 4

strokes of a handgun at each regreasing cycle for bores up

to 50 mm. For bores greater than 50 mm up to 130 mm add 8

strokes of handgun at each regreasing cycle. For bores greater

than 130 mm add 16 strokes of a handgun at each regreasing

cycle. For units running above 80% of maximum RPM, running

temperature should be monitored. If a drastic change in running

temperature is noted, it is recommended to remove the used

grease completely and recharge with fresh grease per the

above instructions.

Select a grease with a viscosity at operating temperature

which will provide full film lubrication (See Table 7). Use a

30°C-55°C increase in bearing temperature above ambient,

depending on RPM and load. Use Table 8 as a general guide for

regreasing the bearings. A small amount of grease at frequent

intervals in preferable to a large amount of grease at infrequent

intervals. For special applications involving high speeds or high

temperatures consult your local ABB Motors and Mechanical

representative for MPT products.

Applications such as conveyor pulleys and fans are shipped

to a job site with bearings already mounted to the shafts.

Since these units may be stored for long periods of time in

unprotected areas subject to rain, dust, etc., bearings should be

packed 100% full and so tagged at bearing assembly to prevent

contamination or corrosion of the bearings.

Summary of Contents for DODGE USN 500 Series

Page 15: ...15 ...