1VAL050503-MB Rev B Replaces (1VAL057485-MB Rev. C) Oct 2013

27

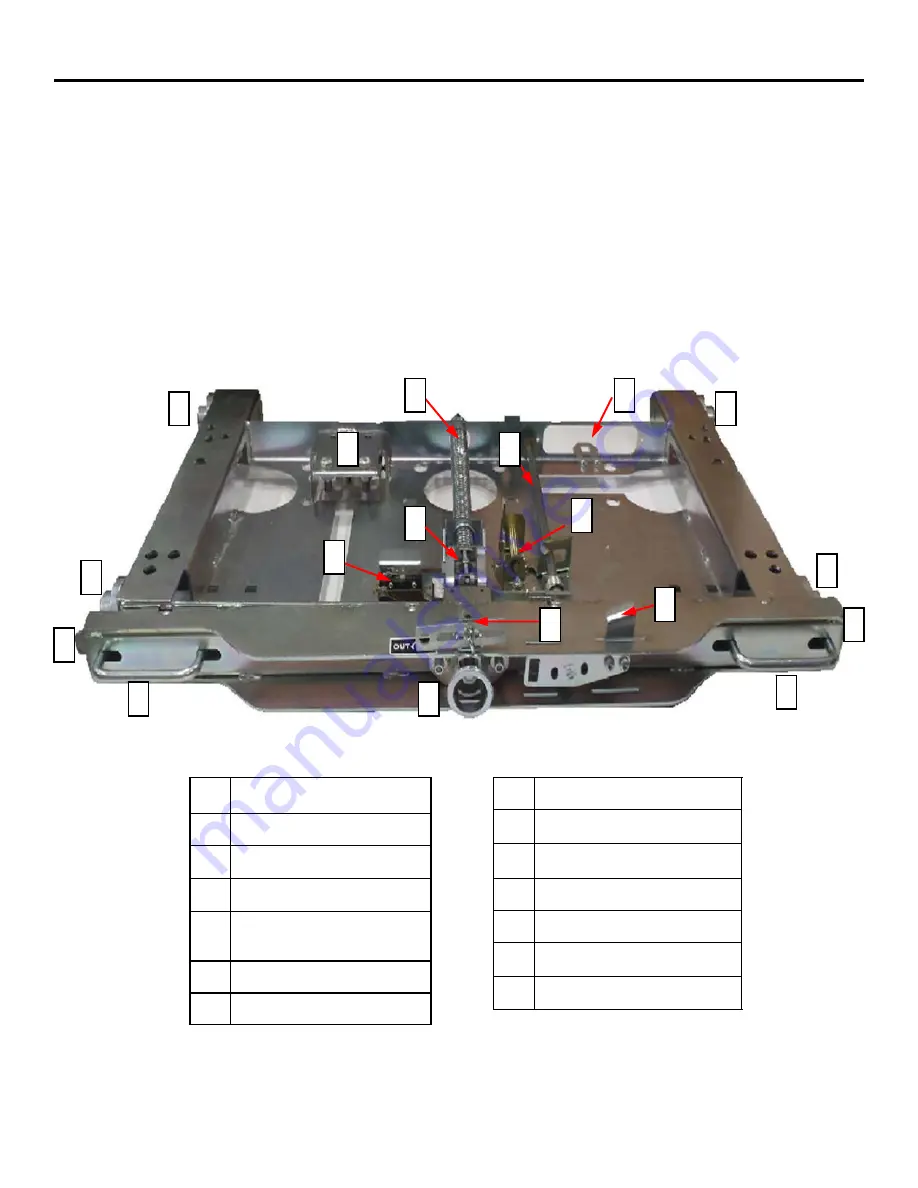

MAINTENANCE

T

RUCK

:

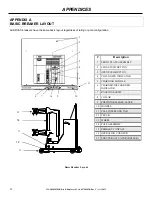

The truck requires visual inspection of hardware, lubrication and operations during routine maintenance.

With the breaker outside the cell, verify all visible hardware tightness, including handles (9) and wheels (7). Wheels

should rotate freely by hand movement. Replace or tighten any missing or loose hardware.

With the breaker outside the cell, rotate the racking screw as though racking the breaker to the connect position. This

process will expose surfaces inside the truck that need to be inspected and lubricated. Lubricate the exposed parts;

specifically the entire Racking Screw (2) and Position Release Shaft (3) assemblies during the operation. Inspect

breaker locking tabs (8) and Secondary Locking Tab (1) for any damage. Return truck to disconnect position. As a

precaution, do not operate the breaker outside the cell unless the truck is in the full disconnect position.

Figure 3: (Truck shown with breaker removed)

1

Secondary Locking Tab

2

Racking Screw

3

Position Release Shaft

4 Grounding

connection

5

Racking Pin Monitor / Close

blocking switch

6

Position Release Lever

7 Wheels

8

Cell Locking Tabs

9 Insertion/Removal

Handles

10

Racking Screw Collar

11

Racking Lock for tagout

12 Spring

Charged

Interlock

13 Racking

pin

14

Breaker open Interlocks

1

2

3

4

5

6

7

7

7

7

8

8

9

9

10

13

11

11