10 Configuration

ACS355 drive configuration

The AC500 Modbus application macro makes the necessary changes to parameter default

values for use in the starter kit. To activate the macro, set parameter 9902 APPLIC

MACRO to AC500 MODBUS (10) as shown below. The macro is available in ACS355

drives with software version 503C or above.

The AC500 Modbus application macro default drive parameters correspond to the ABB

standard macro for ACS355, with the following changes:

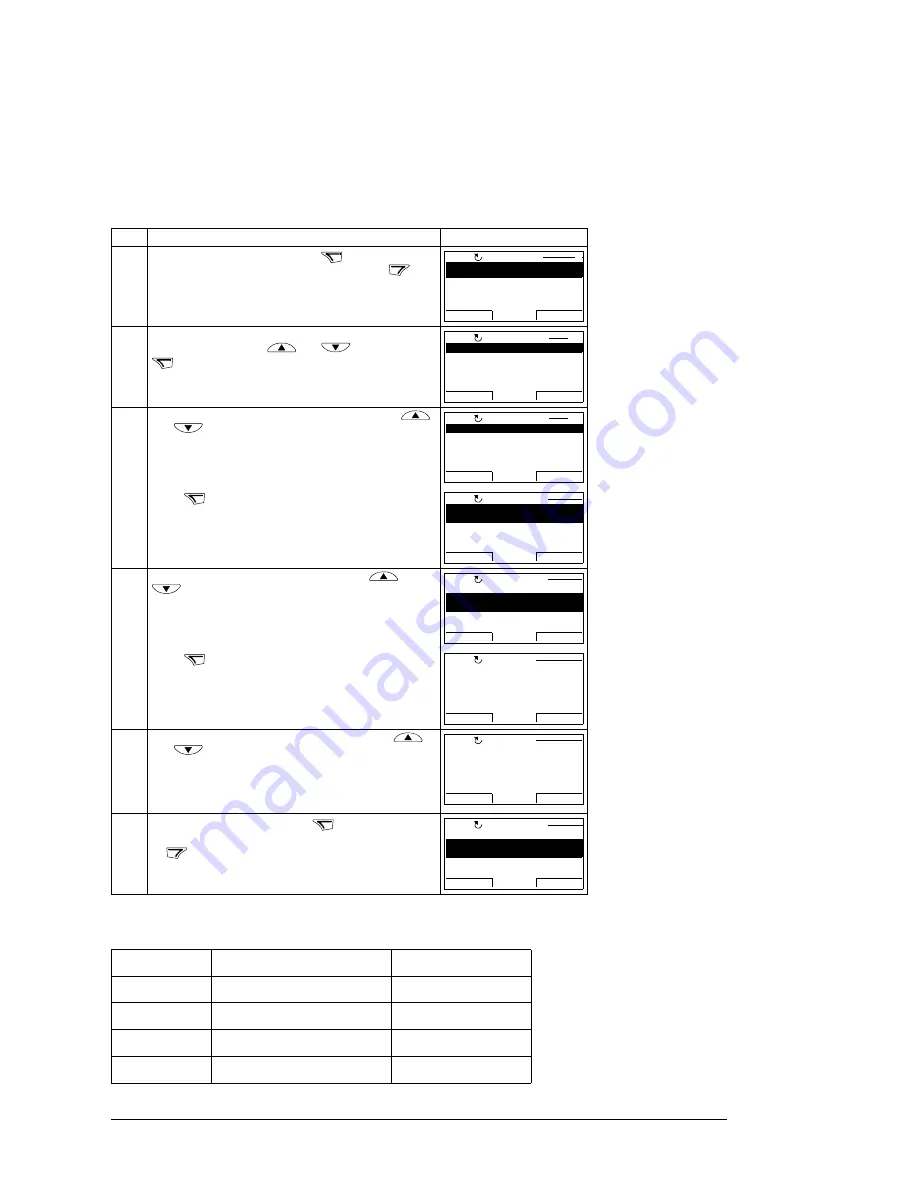

Step Action

Display

1.

Go to the Main menu by pressing

if you are in the

Output mode, otherwise by pressing repeatedly

until

you get to the Main menu.

2.

Go to the Parameters mode by selecting PARAMETERS

on the menu with keys

and

, and pressing

.

3.

Select the appropriate parameter group with keys

and .

Press .

4.

Select the appropriate parameter with keys

and

. The current value of the parameter is shown

below the selected parameter.

Press .

5.

Specify a new value for the parameter with keys

and .

Pressing the key once increments or decrements the

value. Holding the key down changes the value faster.

Pressing the keys simultaneously replaces the displayed

value with the default value.

6.

• To save the new value, press

.

• To cancel the new value and keep the original, press

.

Parameter

Name

Value

1001

EXT1 COMMANDS

COMM (10)

1102

EXT1/EXT2 SEL

COMM (8)

1103

REF1 SEL

COMM (8)

1604

FAULT RESET SEL

COMM (8)

MENU

EXIT

PARAMETERS

ASSISTANTS

CHANGED PAR

EXIT

ENTER

00:00

LOC

MAIN MENU

1

ENTER

01 OPERATING DATA

03 FB ACTUAL SIGNALS

04 FAULT HISTORY

10 START/STOP/DIR

11 REFERENCE SELECT

EXIT

SEL

00:00

LOC

PAR GROUPS

01

99 START-UP DATA

01 OPERATING DATA

03 FB ACTUAL SIGNALS

04 FAULT HISTORY

10 START/STOP/DIR

EXIT

SEL

00:00

LOC

PAR GROUPS

99

SEL

9901 LANGUAGE

ENGLISH

9902 APPLIC MACRO

9903 MOTOR TYPE

9904 MOTOR CTRL MODE

EXIT

EDIT

00:00

LOC

PARAMETERS

9901 LANGUAGE

9902 APPLIC MACRO

ABB STANDARD

9903 MOTOR TYPE

9904 MOTOR CTRL MODE

EXIT

EDIT

00:00

LOC

PARAMETERS

EDIT

9902 APPLIC MACRO

CANCEL

SAVE

00:00

PAR EDIT

[1]

ABB STANDARD

LOC

9902 APPLIC MACRO

PAR EDIT

CANCEL

SAVE

00:00

LOC

[10]

AC500 MODBUS

SAVE

CANCEL

9901 LANGUAGE

9902 APPLIC MACRO

3-WIRE

9903 MOTOR TYPE

9904 MOTOR CTRL MODE

EXIT

EDIT

00:00

LOC

PARAMETERS

AC500 MODBUS

Summary of Contents for ACS355 series

Page 1: ...Application guide ACS355 and AC500 eCo...

Page 4: ......

Page 14: ...14 Configuration The status of the function blocks is displayed...

Page 28: ...28 Function blocks and program structure...

Page 29: ......