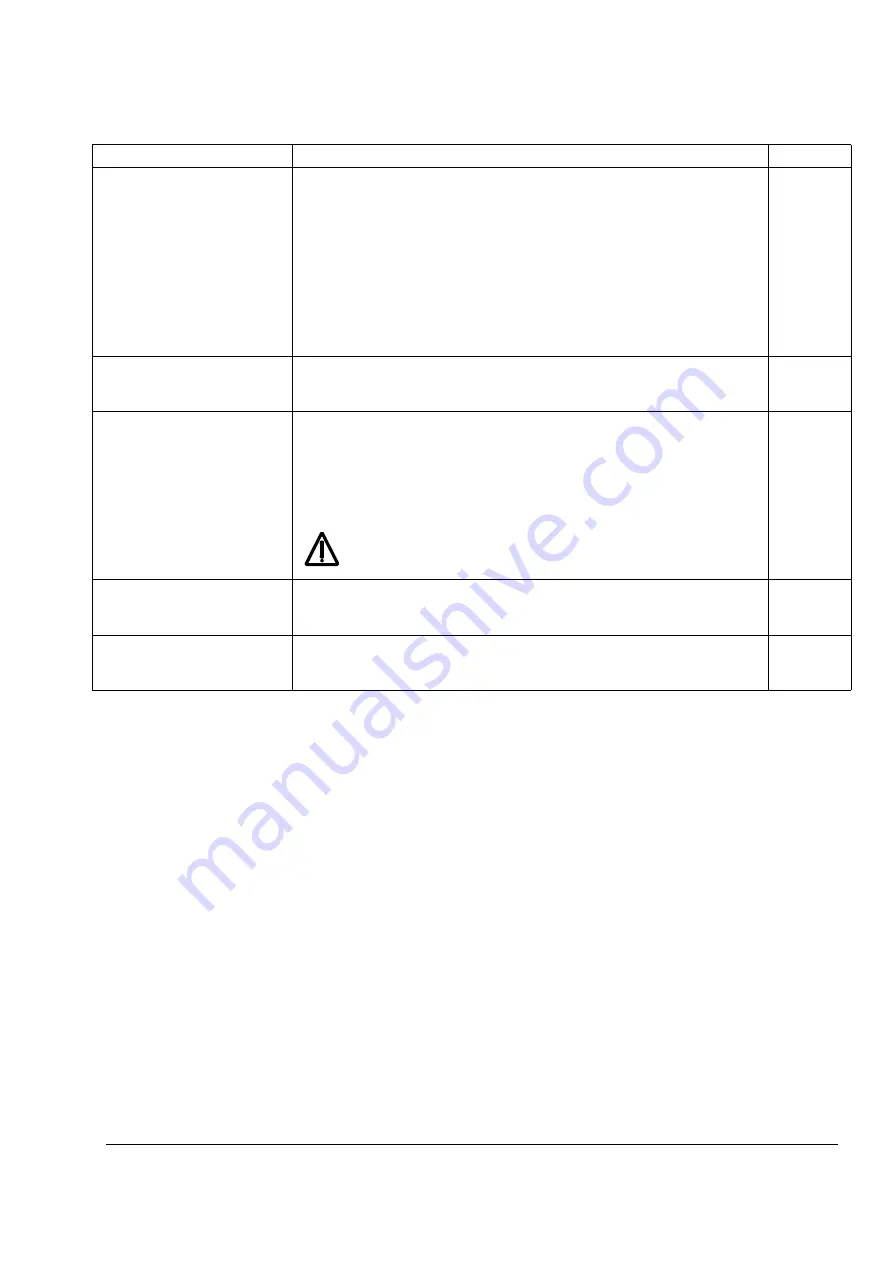

Actual signals and parameters

227

99.10

MOTOR ID RUN

MODE

Selects the type of the motor identification. During the identification, the drive

will identify the characteristics of the motor for optimum motor control. The ID

run procedure is described in chapter

Start-up and control through the I/O

Note:

The ID run (STANDARD or REDUCED) should be selected if:

- The operation point is near zero speed, and/or

- Operation at torque range above the motor nominal torque within a wide

speed range and without any measured speed feedback is required.

Note:

The ID run (STANDARD) cannot be performed if parameter

SCALAR.

ID MAGN

No ID run. The motor model is calculated at first start by magnetising the motor

for 20 to 60 s at zero speed. This can be selected in most applications. The

brake is kept closed during ID MAGN Run.

1

STANDARD

Standard ID run. Guarantees the best possible control accuracy. The ID run

takes about one minute. The brake is opened when STANDARD ID run is

selected. The brake gets closed once the STANDARD ID run is performed.

Note:

The motor must be de-coupled from the driven equipment.

Note:

Check the direction of rotation of the motor before starting the ID run.

During the run, the motor will rotate in the forward direction.

WARNING!

The motor will run at up to approximately 50 … 80% of the

nominal speed during the ID run. ENSURE THAT IT IS SAFE TO RUN

THE MOTOR BEFORE PERFORMING THE ID RUN!

2

99.11

DEVICE NAME

Defines the name for the drive or application. The name is visible on the

control panel display in the Drive Selection Mode.

Note:

The name can be

typed only by using a drive PC tool.

99.12

OEM SIGNAL

Defines the text for the OEM signal. The signal can be displayed on the control

panel display by selecting the actual parameter

Note:

The name can be

entered only by using a drive PC tool.

Index

Name/Selection

Description

FbEq

Summary of Contents for ACS 800 Series

Page 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Page 4: ......

Page 26: ...Start up and control through the I O interface 26 ...

Page 36: ...Quick start up guide 36 ...

Page 52: ...Control panel 52 ...

Page 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Page 128: ...Program features 128 ...

Page 150: ...Application macros control location EXT1 EXT2 150 ...

Page 228: ...Actual signals and parameters 228 ...

Page 299: ...Adaptive Programming examples for crane control 299 ...

Page 305: ...Adaptive Programming examples for crane control 305 ...

Page 318: ...Analogue Extension Module 318 ...

Page 332: ...Additional data actual signals and parameters 332 ...

Page 334: ...DriveWindow 334 ...

Page 335: ...Control block diagrams 335 Control block diagrams ...

Page 336: ...Control block diagrams 336 ...

Page 337: ...Control block diagrams 337 ...

Page 338: ...Control block diagrams 338 ...

Page 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...