Direct I/O Displays

Section 7 I/O Displays

190

3BUR002418-600 A

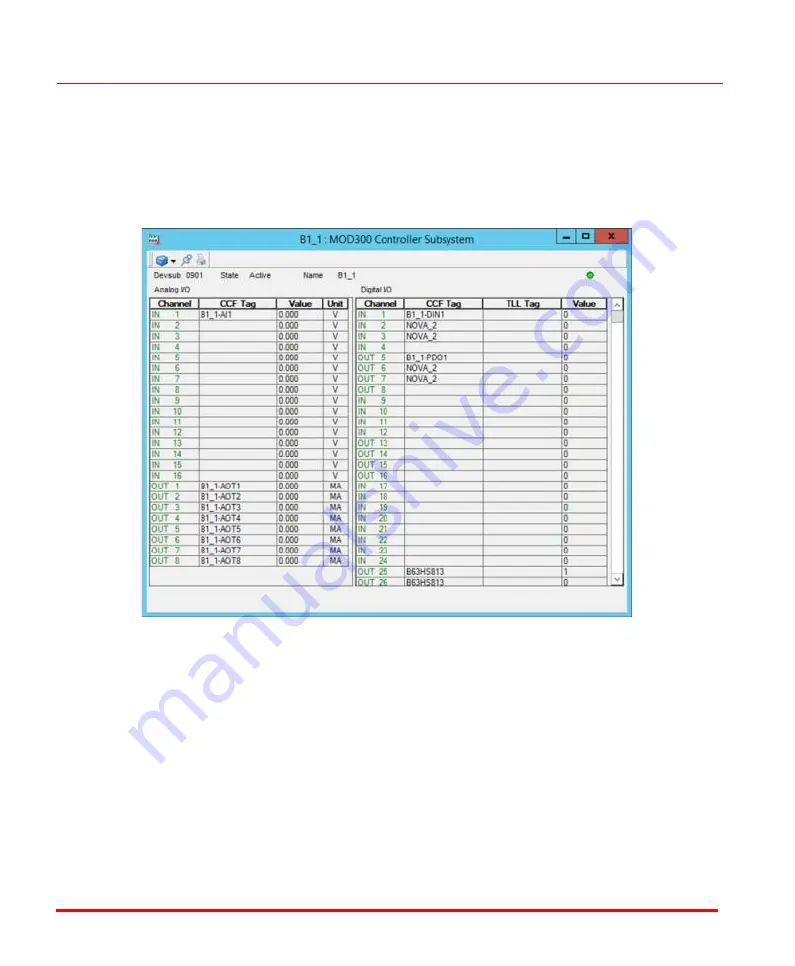

Access the Direct I/O Display,

, from the Controller Subsystem Status

display by selecting an active controller, then selecting the

button

and selecting Controller I/O, Alternately, you can select a direct I/O device in the

Diagnostics window of the Controller Subsystem Status display.

From this display you can:

•

Return to the subsystem status display using the controller context menu (right

click anywhere except in a valid CCF or TLL tag field)

•

Open associated CCF or TLL faceplate for a channel (click on CCF Tag or

TLL Tag for desired channel)

CCF can use any I/O type (Analog Input, Analog Output, Pulsed Input, Digital

Input, Digital Output and Device Loop).

Figure 82. Direct I/O Display

Summary of Contents for Ability 800xA Series

Page 1: ...Power and productivity for a better worldTM 800xA for MOD 300 Operation System Version 6 0 ...

Page 2: ......

Page 3: ...800xA for MOD 300 Operation System Version 6 0 ...

Page 14: ...Table of Contents 14 3BUR002418 600 A ...

Page 74: ...Area Graphic Display Section 3 CCF Displays 74 3BUR002418 600 A ...

Page 102: ...Batch Connectivity to M0D 300 Section 4 TCL Displays 102 3BUR002418 600 A ...

Page 120: ...TLL Messages Section 5 TLL Displays 120 3BUR002418 600 A ...

Page 212: ...Viewing Abnormal State on MOD Loop Displays Section 8 Operation Examples 212 3BUR002418 600 A ...

Page 320: ...BRKPTS Appendix A Runtime Templates 320 3BUR002418 600 A ...

Page 322: ...Updates in Revision Index A 322 3BUR002418 600 A ...

Page 330: ...Index 330 3BUR002418 600 A ...

Page 331: ......