22

1.

Set the

ON/OFF

power Switch to

"

OFF

".

2.

Turn the regulator knob

counterclockwise to set the outlet

pressure to zero.

3.

Remove the air tool or accessory.

4.

Place a suitable container under

the drain valve to catch discharge.

5.

Pull ring on safety valve allowing air

to bleed from the tank until tank

pressure is approximately 20 psi.

Release safety valve ring.

6.

Drain water from air tank

unthreading the Drain Valve two or

three turns

ONLY

.

7.

After the water has been released,

close the drain valve

.

CAUTION!

Do not open the

Drain Valve so that more than four

threads .

The air compressor can now be stored.

TO REPLACE REGULATOR

WARNING:

Risk of unsafe

operation. Unit cycles automatically

when power is on.

When performing maintenance, you

may be exposed to voltage sources

,

compressed air, or moving parts.

Personal injuries can occur. Before

performing any maintenance or repair,

disconnect power source from the

compressor and bleed off all air

pressure and allow the air compressor

to cool.

1.

Release all air pressure from air tank.

See To Drain Tank in the Maintenance

section.

2.

Unplug unit.

3.

Remove the console cover.

4.

Using an adjustable wrench remove

the safety valve from the regulator

manifold.

5.

Remove the hose by removing the

hose clamp.

NOTE:

The hose clamp is not

reusable. You must purchase a new,

standard hose clamp at a local

hardware store.

6.

Remove pump mounting screws

securing pump (one on each side).

7.

Carefully slide pump from brackets

and out of the way.

8.

Using an adjustable wrench remove

the regulator manifold .

9.

Apply pipe sealant to new regulator

manifold and assemble, tighten with

wrench.

10.

Reapply pipe sealant to safety valve.

11.

Reassemble all components in

reverse order of removal. Make sure

to orient gauges to read correctly

and use wrenches to tighten all

components.

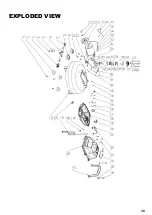

Summary of Contents for A12101

Page 30: ...30 EXPLODED VIEW...