TMC-4 Control Card

for Electric Actuators

Installation & Maintenance Manual

18

04/06/22

www.atcontrols.com

IOM08139 REVISION 04

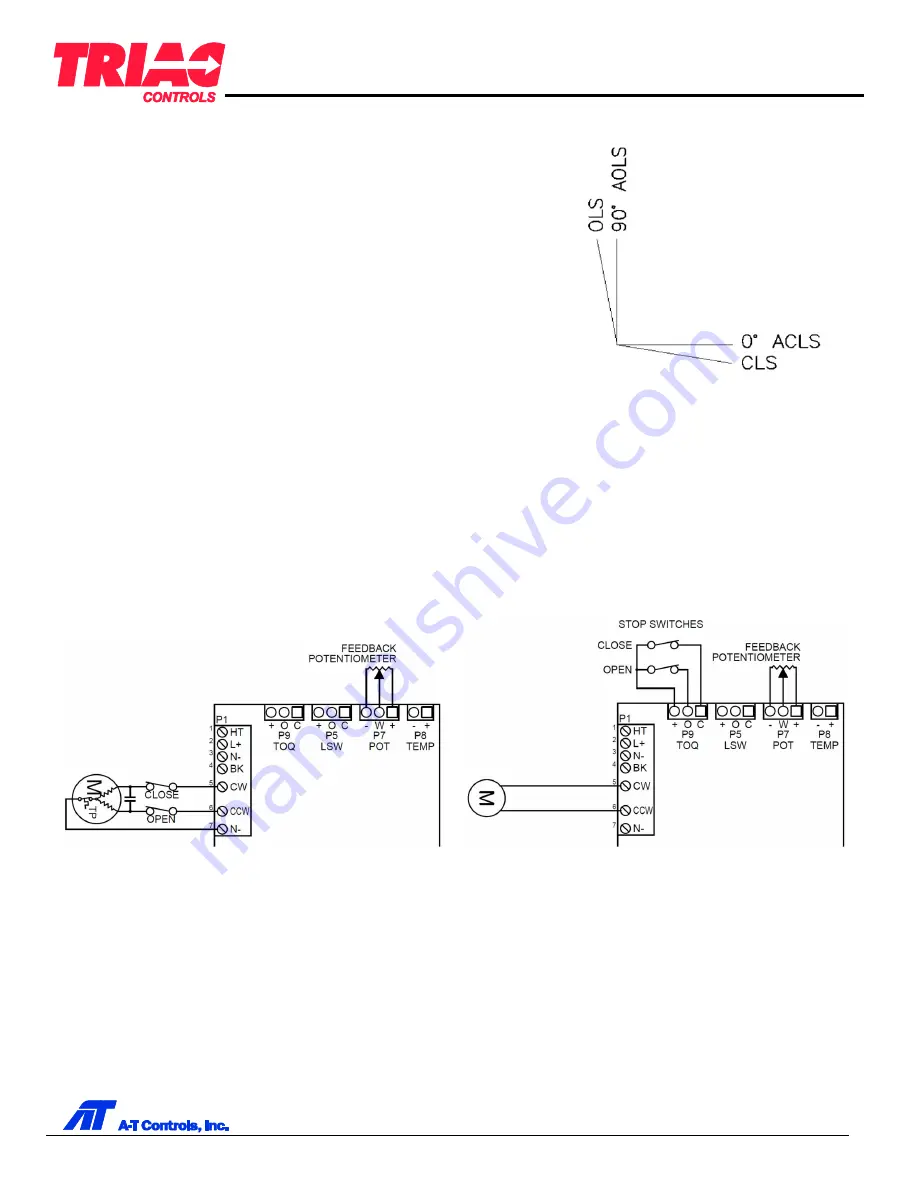

4.1.2. Position Limit Switch (P5)

Position limit switches connected to header (P5) are used to detect the Open

and Close position of the actuator for two position and on/off applications.

These switches will stop the actuator at the limits and provide Open or Close

status indication to the TMC4 when “Position Type” is set for Limit Switch in

POSITION CONFIG

submenu.

Typically, the auxiliary switches (AOLS and ACLS) in an actuator would be

used, and the motor travel stop switches (OLS and CLS) would be set just

outside of the operating range. The “Switch Action” setting in the

POSITION

CONFIG

submenu must be set according to if using normally open contact

(N.O. switch action) or a normally closed contact (N.C. switch action).

4.1.3. Stop/Torque Limit Switch (P9)

Motor travel stop or torque switches connected to header (P9) are used to stop the actuator regardless of set position

limits. This switch input should be used when the TMC4 motor outputs are not wired through limit switches, such as for

DC motors. This switch input provides no position indicator for the TMC4 since if an in-line switch stopped the motor from

some over torque situation, a false Open or Close status may be given.

When the motor outputs are wired through limit or torque switches, the switches should be connected through the N.C.

contact to open the motor circuit when activated. As such, the switches connected to the Stop/Torque input (P9) should

preferably also use a N.C. contact configuration. Ensure “Switch Action” setting in the

POSITION CONFIG

submenu is set

for N.C. action for the stop/torque switches.

AC

DC

Motor outputs connected to motor through switches.

Stop/Torque switch input not required.

Motor outputs connected directly to motor.

Stop/Torque switch input required.