Page 14

VTX series instructions

wrong voltage, will normally still go approximately

at its designed speed. This is because its field current

reduces (or increases) in proportion and the motor

speed has to increase (or decrease) proportionally to

compensate.

The nameplate current quoted for motors is normally

a continuous rating: most motors will safely take an

overload of about 400% for short periods. The

current the motor actually requires is determined by

the mechanical loading, not by the controller or the

motor. If the motor is too small, it will overheat and

if the controller is too small, then it will overheat. For

more information on motors, contact 4QD.

Faults are not ‘common’: as soon as 4QD find a fault

which occurs often enough to recognise it as a

problem, we try to alter the design to eliminate it.

This policy makes it difficult to give you sensible

fault finding tips - but it does improve our product!

The vast majority of controllers returned have no

fault, or simply a fuse track has been blown by a

wiring fault (see back page for fuse information). Of

the rest, most failures are due to misuse, albeit often

through misunderstanding.

We cannot do a lot about external wiring faults

except to protect the controller as much as possible.

However if a bad fault occurs in the controls

(connected to the 6 pin input connector) the controller

has been designed to protect itself and minimise

damage. So there are weak points (fuse tracks) in the

controller intended to limit the damage- see opposite.

Sometimes wiring faults (e.g. a short b24v

and the pot) will feed current back into the controller

and blow the 9v1 zener diode. This usually fails safe

(short circuit) so that there is no voltage feed to the

pot. This is probably a return to base repair - unless

you feel confident with a soldering iron, in which

case ask us for help.

The zener can also be blown sometimes by

mishandling, e.g. disconnecting the controller than

putting it down on a metal object: the main capacitor

stores charge for q considerable time.

Some problems are caused by the wrong wire in the

IDC connectors.

MOSFETs do fail occasionally: they are doing an

enormous amount of work and sometimes one simply

gives up: commonly the drive MOSFETs cause their

drive resistors to burn up - a sure sign the MOSFET

has failed.

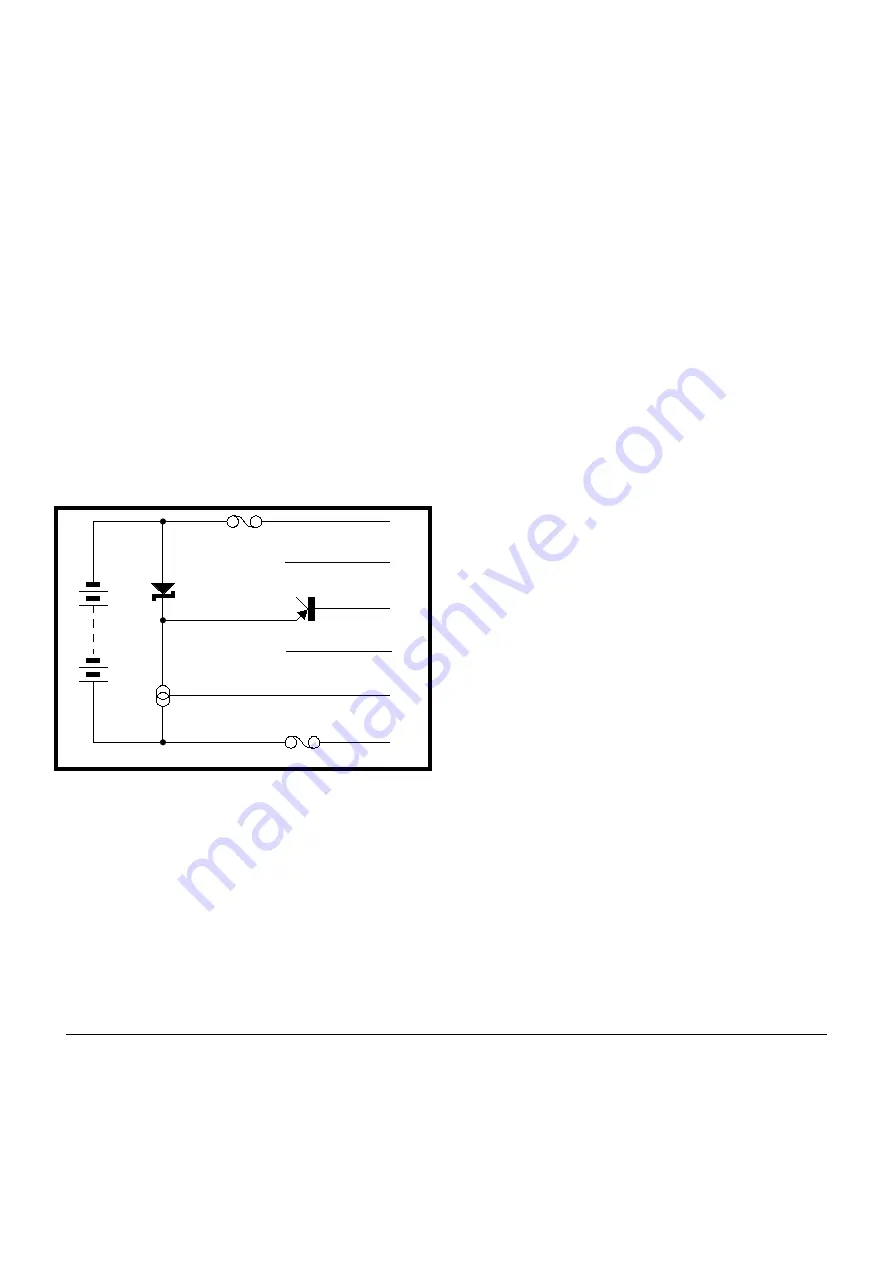

An understanding of the internal powering

arrangements may help you find problems (both in

the controller and in your wiring).

Connecting the ignition to battery positive turns on a

current source (about 30mA) which powers all the

internal circuitry, using a 9v1 zener diode as a

regulator. This system is very reliable as it tends to

fail safe: zeners when overloaded usually fail short

circuit, which removes all internal power.

The 9v1 line is fed to the top of the pot via a

transistor (which detects open circuit pot wiring), so

when the internal supply is powered up you can

measure about 8.5v across the pot. Operating the pot

will, then, change the blue wire to pin E from 0v to

8.5v, depending on the pot setting.

Main capacitor:

Be aware that certain uses of the controller can cause

this to heat, particularly if the battery leads are long.

The main capacitor may get warm, but should not be

allowed to remain hot to touch for too long. Heating

will shorten the life of this capacitor and, if

excessive, can cause it to vent. When it vents, the

liquid electrolyte inside boils and vents. Although the

capacitor failing does not do any direct damage (the

controller simply looses power) the venting capacitor

can expel hot electrolyte: if this gets on to the wrong

9v1 zener

current source

b

ignition

reverse

pot top

pot wiper

pot zero (batty -)

pot fault detector

A

B

C

D

E

F

F2

F3

15: Common faults