10

3M™ MicroTouch™ Controller RX181 Reference Guide

3M Touch Systems, Inc. Proprietary Information

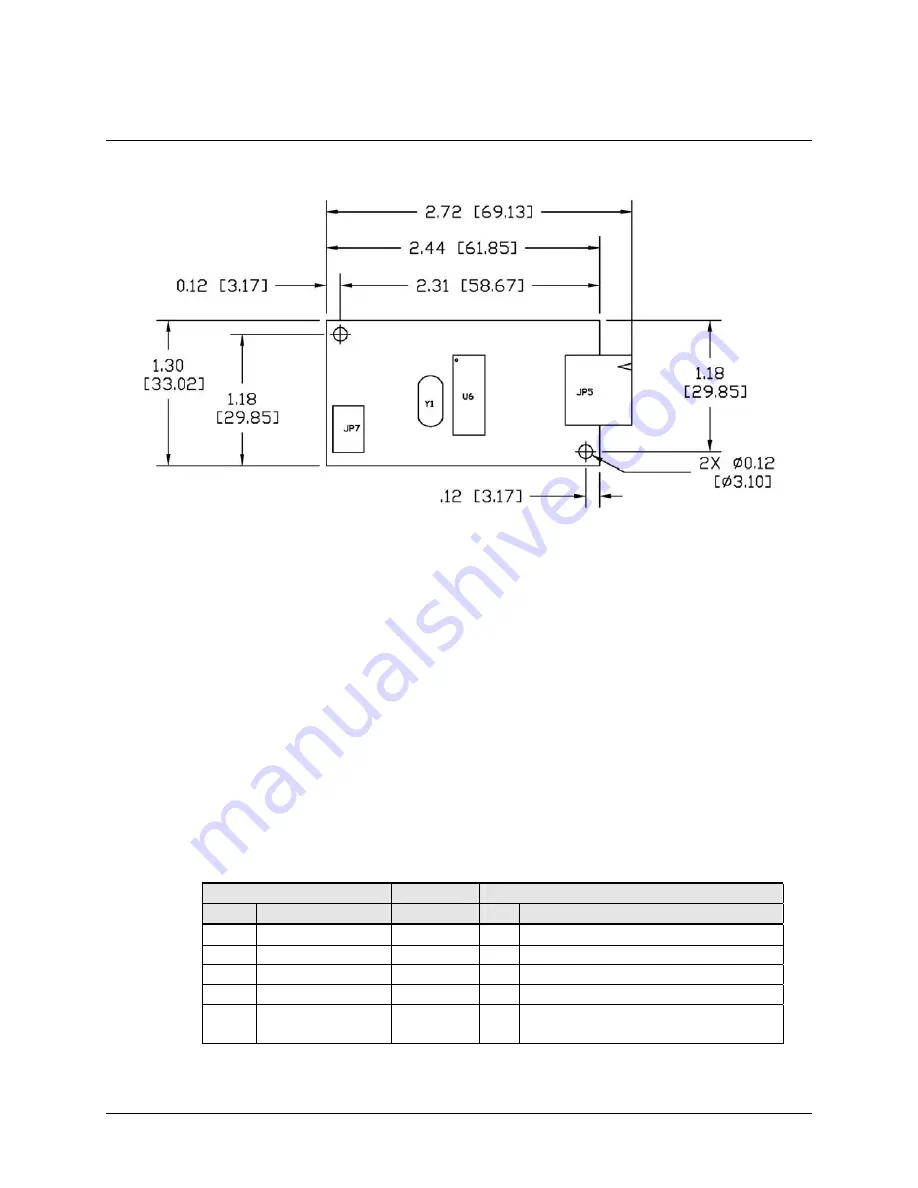

Figure 1. RX181 Controller Overall Dimensions

Handling and ESD Protection

When mounting the sensor and controller, use normal precautions for handling

electrostatic sensitive devices. The RX181 has internal protection to ±20 kV for ESD air

discharges to the sensor (not to the controller directly) that may occur during normal

operation of the sensor. Refer to Appendix A for further specifications.

Establishing the Data Connection

The RX181 controller requires a 3M™ MicroTouch™ USB communication cable (P/N

7319420) PC 99 compatible or an equivalent interconnect. One end of this cable plugs

into the USB connector (JP7) on the RX181 controller. The other end, which has a Type-

A connector, plugs into a USB port on your PC.

When creating a custom cable, use the Molex 51004-0500 mating connector. Table 1

describes the interconnections of the 3M™ MicroTouch™ USB cable.

Table 1. USB Cable for RX181 Controllers

PC Side (USB Type A) Wire

Controller Side (5-Pin Molex)

Pin

USB Assigned

Color

Pin Description

1

+5Vdc

Red

1

+5Vdc Input Power

2

Data (DN)

Gray

2

Data (DN) Differential Pair

3

Data (DP)

Green

3

Data (DP) Differential Pair

4 0V

Black 4

Power

Return

5

Cable Shield Shell Charcoal

Gray

5

Outer Cable Shield around signal and

power lines. Chassis (earth) ground