8

2.7

SHARP EDGES:

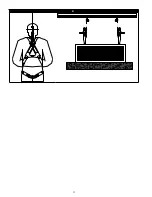

Avoid working where Lifeline or Lanyard components of the Personal Fall Arrest System (PFAS) can

contact or abrade against unprotected sharp edges (see Figure 4). Where contact with a sharp edge is unavoidable, cover

the edge with protective material (A).

2.8

COMPONENT COMPATIBILITY:

3M equipment is designed for use with 3M approved components and subsystems

only. Substitutions or replacements made with non-approved components or subsystems may jeopardize compatibility of

equipment and may effect the safety and reliability of the complete system.

2.9

CONNECTOR COMPATIBILITY:

Connectors are considered to be compatible with connecting elements when they

have been designed to work together in such a way that their sizes and shapes do not cause their gate mechanisms to

inadvertently open regardless of how they become oriented. Contact 3M if you have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable of supporting at least 5,000 lbs. (22.2 kN). Connectors

must be compatible with the anchorage or other system components. Do not use equipment that is not compatible.

Non-compatible connectors may unintentionally disengage (see Figure 5). Connectors must be compatible in size, shape,

and strength. If the connecting element to which a snap hook or carabiner attaches is undersized or irregular in shape, a

situation could occur where the connecting element applies a force to the gate of the snap hook or carabiner (A). This force

may cause the gate to open (B), allowing the snap hook or carabiner to disengage from the connecting point (C).

Self-locking snap hooks and carabiners are required by ANSI Z359 and OSHA.

2.10 MAKING CONNECTIONS:

Snap hooks and carabiners used with this equipment must be self-locking. Ensure all

connections are compatible in size, shape and strength. Do not use equipment that is not compatible. Ensure all

connectors are fully closed and locked.

3M connectors (snap hooks and carabiners) are designed to be used only as specified in each product’s user’s instructions.

See Figure 6 for examples of inappropriate connections. Do not connect snap hooks and carabiners:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

Large throat snap hooks should not be connected to standard size D-rings or similar objects which will result in

a load on the gate if the hook or D-ring twists or rotates, unless the snap hook complies is equipped with a 3,600

lb (16 kN) gate. Check the marking on your snap hook to verify that it is appropriate for your application.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the anchor, and

without visual confirmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the lanyard and

connector specifically allows such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and lock, or that

roll-out could occur.

G. In a manner that does not allow the connector to align properly while under load.

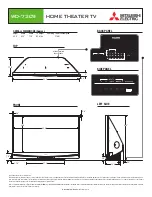

Summary of Contents for DBI SALA FLEXIGUARD Glyde-Saf HD System

Page 3: ...3 6 A B A B 50 ft 15 2 m 6 ft 1 8 m 6 ft 1 8 m 7 8 ...

Page 4: ...4 9 ...

Page 13: ......