North American - ENG

Date Released:

05-22-18

3M-Matic

™

Accuglide 4 - 2 and 3 Inch Taping Head - Type 11800

Page 17

44-0009-2146-8 / ECO# 0078045

Cause

The tape is threaded incorrectly

The tape tension is too low

The knurled roller drags

Tape tracks to one side or drags

on the support tabs of applying

frame

Taping head is not set up properly

The blade is dull and/or has

broken teeth/adhesive build up/

dry blade/blade in backwards

Tape tension is insu

ffi

cient or

too high

The blade is not positioned

properly

One or both cutter springs are

missing or stretched

Tension roller surface is not fully

contacting the taping head frame

Correction

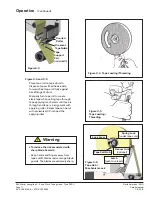

The tape must go around the

wrap roller before going around

the one-way tension roller

Adjust the one-way tension roller

Check for adhesive build-up

between the knurled roller and its

shaft. Clean and lubricate shaft.

Remove all lubricant from roller

surfaces.

Adjust the tape web alignments

Readjust the machine’s center

alignment setting

Check the position of the tab

adjustment roller and adjustment

bar

Re-adjust sealer so bottom

of taping head is ¼” from top

surface of carton.

Clean and adjust / Grease blade

grease pad /replace the blade

Increase/decrease tape tension

by adjusting the one-way

tension roller

Tighten or loosen hub adjustment nut

Make sure the blade is correctly

positioned. Mount the blade so

that the beveled edge is away

from the entrance of the head

Replace the defective spring(s)

Make sure one-way bearing is

below the surface of the tension

roller. If not, press bearing further

into roller or replace roller

Troubleshooting Guide

Problem

The tape leg on the front of the

case is too long

The blade does not cut tape or

tape end is jagged/shredded/

stretching or wrinkling

Troubleshooting

(continued on next page)