User Guide for 4 axis TB6560 driver board

Product Features:

Toshiba TB6560AHQ chip - High power, maximum 3.5A drive current chipset !

1-1/16 microstep setting - Higher accuracy and smoother operation than standard 1, 1/2 step!

Adjustable 1.5A-3A drive current settings for each axis - 25%,50%,75%,100% of full current can be set for

different stepper motors

Overload, over-current and over-temperature safety - Full protection for your computer and peripheral

equipment !

On board current switching - Power output can be set according to specific user requirement !

Full closed-type optical isolation to protect the user's computer and equipment

Relay spindle interface - Outputs Max. 36V 7.5A for spindle motors or coolant pump (only one device can be

powered by this output!)

4 channel inputs interface- Can be used for XYZ limit and emergency stop !

Professional design - Two stage signal processing with super anti-jamming !

Bipolar constant current chopper drive with non-resonant region - Controls motors smoothly through range

without creep effect !

Four control inputs (divided into pairs of knives) - Allows setting of limit and emergency stop !

Universal architecture - Supports most parallel software MACH3,KCAM4 etc!

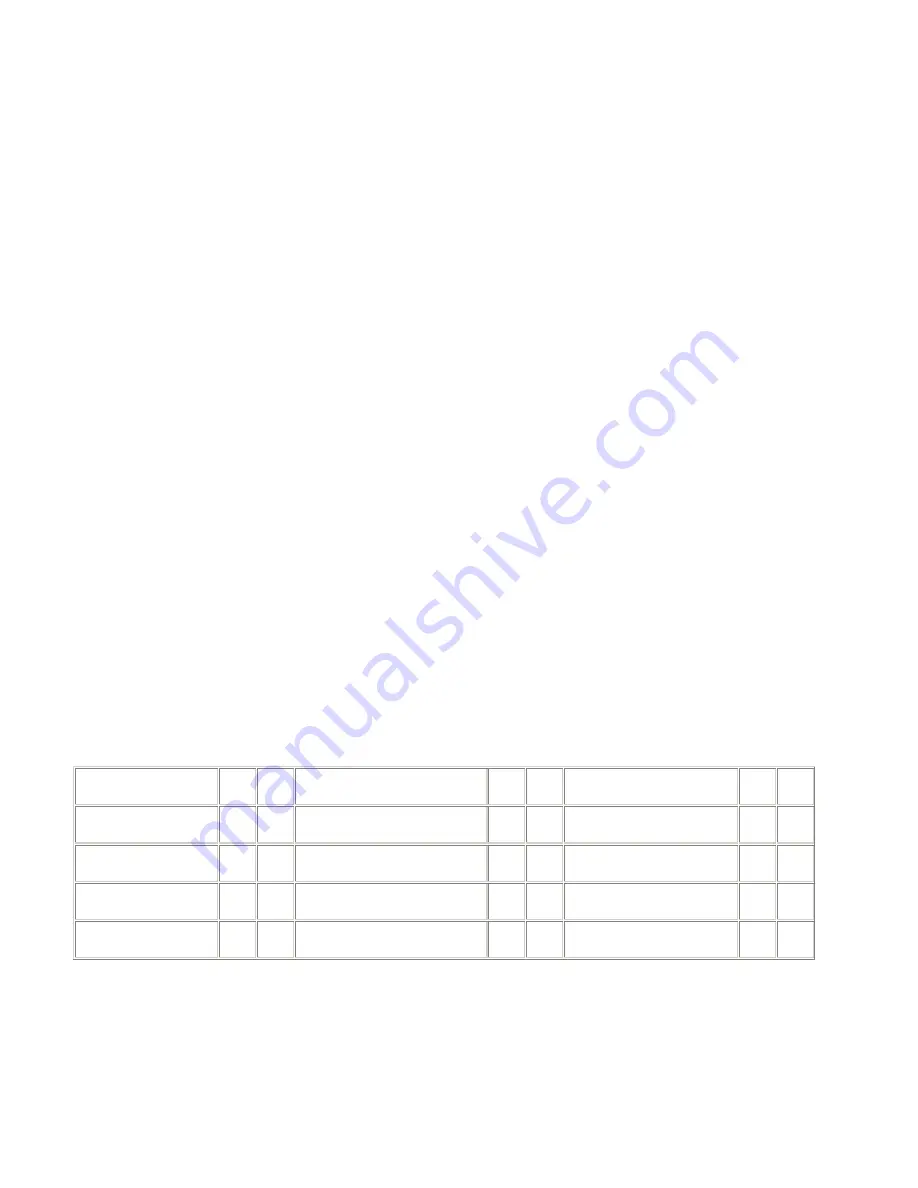

Dip settings:

Current Setting

1

2

Decay Mode Settings

3

4

MicroStep Settings

5

6

100%

ON ON

FAST

ON ON

1

ON ON

75%

ON OFF

25%

ON OFF

1/2 ON

OFF

50% OFF

ON

50%

OFF

ON 1/8 OFF

ON

25% OFF

OFF

SLOW

OFF OFF

1/16 OFF OFF

* Important Notes:

Power supply DC 12-36V

(not included)

*Voltage Selection:

12-16V DC power supply for Nema 17 stepper motors