Reviews:

No comments

Related manuals for Networking C9010

700 Series

Brand: N-Tron Pages: 101

2210

Brand: IBM Pages: 72

Express Ethernetwork DI-704P

Brand: D-Link Pages: 2

Express Ethernetwork DI-704P

Brand: D-Link Pages: 17

DSL-2750U

Brand: D-Link Pages: 2

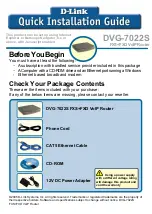

DVG-7022S

Brand: D-Link Pages: 7

DIR-878

Brand: D-Link Pages: 41

DES-1228/ME

Brand: D-Link Pages: 267

Air DCS-1000W

Brand: D-Link Pages: 13

AP200

Brand: Watchguard Pages: 40

AirPlus DWL-810

Brand: D-Link Pages: 25

AirPlus DWL-810

Brand: D-Link Pages: 8

DSL-500

Brand: D-Link Pages: 11

DHP-601AV

Brand: D-Link Pages: 84

Verizon DSL-2750B

Brand: D-Link Pages: 2

DVA-2800

Brand: D-Link Pages: 4

AirPlus G DWL-G710

Brand: D-Link Pages: 5

AC750

Brand: D-Link Pages: 12