Tips for cutting

156

5.7 Tips for increasing the rate of production

For high production speeds with good quality,Zünd recommends the following method:

• Set the holding times for the tool (Before Down, After Down, Before Up, After Up) to 0 ms. This is

usually necessary for tools with a pneumatic Z-axis.

• To raise the tool, set the maximum values for the speed and acceleration parameters.

• To lower the tool, set the maximum values for acceleration or speed.

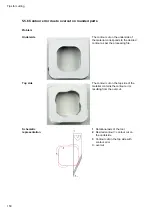

5.8 Identifying and rectifying quality problems

Curves cut inaccurately

Acceleration/speed is too high.

Reduce acceleration/speed.

1-1-1-3-2 Speed

Processing data are of poor quality.

Revise the processing data. Send curves

to the cutter as arc functions.

-

Wrong blade in relation to material

type, material thickness, or cutting

contour.

Select a blade which is appropriate to the

material, material thickness and cutting

contour. For help with selecting the

right one, refer to the Zünd accessories

catalog.

-

Cutting distortion of curves due to blade overcut

Due to the geometry, the blade

produces a large overcut

Select a blade which is appropriate to the

material, material thickness and cutting

contour. For help with selecting the

right one, refer to the Zünd accessories

catalog.

-

The overcut correction is not set.

Set the overcut correction. Enter

overcut/2 as correction value.

1-1-1-4-2

Correct X

Jerky, stuttering cutter movement

Processing data are of poor quality.

Revise the processing data. Send curves

to the cutter as arc functions.

-

The acceleration is too high

Reduce the acceleration

1-1-1-3-3

Acceleration

The vector intermediate angle, for

which the speed is reduced to zero if

this angle is exceeded, has been set

too small.

Check the stop angle (may be too small

– enlarge) adjust vectors.

Содержание S3 M-1200

Страница 1: ...Operating Manual S3 Digital Cutter ...

Страница 5: ...Contents 5 8 Modules 209 9 Material handling 211 10 Additional specifications 213 ...

Страница 6: ...Contents 6 ...

Страница 10: ...Introduction 10 ...

Страница 14: ...Product description 14 2 5 Cutter overview ...

Страница 38: ...Product description 38 ...

Страница 64: ...Safety 64 ...

Страница 90: ...Controls and operation 90 4 13 3 Inserting replacing the module ...

Страница 103: ...Controls and operation 103 Plastic perforated plate Adjustable vacuum range Leather no ...

Страница 134: ...Controls and operation 134 ...

Страница 139: ...Tips for cutting 139 T Material thickness Z Set depth TM Cutting depth material thickness t set depth z ...

Страница 155: ...Tips for cutting 155 5 6 2 Calculation of maximum speed for EOT POT Z16 Z42 ...

Страница 161: ...Maintenance 161 Description Task marker pen slotted screwdriver needle nosed pliers cutter blades ...

Страница 187: ...Maintenance 187 B Cut the conveyor belt using scissors and remove it C Dispose of the conveyor belt correctly ...

Страница 207: ...Tools 207 7 Tools ...

Страница 208: ...Tools 208 ...

Страница 209: ...Modules 209 8 Modules ...

Страница 210: ...Modules 210 ...

Страница 211: ...Material handling 211 9 Material handling ...

Страница 212: ...Material handling 212 ...

Страница 213: ...Additional specifications 213 10 Additional specifications ...

Страница 214: ...Additional specifications 214 ...