LINEUP ASSEMBLY

Zero Zone display cases have been engineered for continuous display. This means that any number of cases can be joined together to

create a display of any desired length. The bottom of the end panel is protected with a removable steel plate.

The lineup is assembled by sliding one case up to the second case and then bolting the cases together. Bolt holes for the bottom of the

frame can be accessed by removing the right and left coil covers. The front and top bolt holes are visible on the steel end frame. The rear

bolt holes are exposed by removing the lift-out duct on the 30" door cases and by removing pocket covers on the 24" door cases.

show the bolt hole locations for each case. Bolt kits and instructions are supplied with the case.

gives instructions on applying caulk to the case joint before the cases are slid together. Once the cases have been caulked and

slid together, start the joining bolts, but do not tighten them. Slide the t-strip between the door frames (

). Begin

tightening the bolts at the top rear, working down the back of the case and up the front, making sure that the front seams are flush. Bolts

are not designed to pull the cases together.

Two different model cases or two different temperature cases are connected using an insulated divider. Typically the divider is factory

assembled to one of the cases. Two styles of divider are provided. The first style has a panel on each side with nut inserts in the panels.

Each side is bolted to the end frame. Instructions for assembly of this style are given in

divider uses a thru-bolt design. The divider is attached to one of the cases using short bolts. When the case is installed, the short bolts

are removed and long bolts are reinstalled to bolt both cases together. Instructions for assembly of this style case are given in

. Bolts are not designed to pull the cases together.

.

The end panel protector support plates should be removed after the cases are set in their final position.

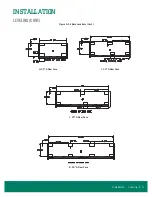

Figure 9: Caulking Cases to be Joined

DO NOT APPLY EXCESS AMOUNTS OF BUTYL SEALANT THAT WOULD CAUSE IT TO SQUEEZE ONTO END FRAME

METAL AREAS.

Caulk sealant used to join cases and complete the sealing requirements for NSF compliance should not come

in contact with butyl sealant. Apply to clean, dry surfaces free of contaminants that adversely affect adhesion and could change

color of sealant joint areas over time.

PROCEDURE FOR JOINING CASES

These procedures are critical! Failure to follow these guidelines

will result in a poorly functioning case. This is especially true of

low temp cases.

1. Apply two

1/4

" to

3/8

" wide beads of butyl sealant,

1/2

" in from

the inside and outside edges of foamed insulated ceiling, rear

wall, base, and door frame to be joined. Apply to only one

case joint to avoid excessive amounts of butyl sealant that

would squeeze out of the joint. Sealant is not applied to the

structural steel end frames. After cases are joined, caulk the

top and back exterior seams (if possible) at this time.

2. When joining ends of cases, caulk sealant should be applied

in the same manner for joints.

A

B

Remove (4) Filler Blocks If

Applied To Inside Of Base

Ends Before Joining Cases

DETAIL A

DETAIL B

1/4" - 3/8" Typ.

Butyl Sealant

Beads

1/4" - 3/8" Typ.

Butyl Sealant

Beads

DWG NO.SP-6005-1REV. B

TOLERANCES:

(PER SP-0457)

(NONE)

RELEASED

PART WEIGHT:

(IN LBS)

CAD DRAWING

NO MANUAL REVISIONS

COPYRIGHT INFORMATION

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN, IS

THE SOLE PROPERTY OF ZERO ZONE, INC. ANY USE OF THIS

DOCUMENT OR DISCLOSURE OF ITS CONTENTS; BY

REPRODUCTION OR OTHER MEANS, WITHOUT THE WRITTEN

CONSENT OF ZERO ZONE, INC. IS STRICTLY PROHIBITED.

(NONE)

(NONE)

FINISH:

(PER SP-0154)

MATERIAL:

(PER SP-0404)

(UNLESS OTHERWISE SPECIFIED)

A

SHEET

SIZE

NOT TO SCALE

JZ

SCALE:

MODELED BY:

DRAWN BY:

UNLESS OTHERWISE

SPECIFIED, ALL DIMENSIONS

ARE IN DECIMAL INCH

9/13/2012

B

1 OF 1

SP-6005-1

JOINING CASES

SHEET:

DATE:

REVISION

ZERO ZONE, INC.

110 NORTH OAKRIDGE DRIVE

NORTH PRAIRIE, WISCONSIN

USA 53153

DRAWING No:

DESCRIPTION:

BY

DATE

ECN No.

REVISION DESCRIPTION

No.

JZ

9/13/2012

9651

UPDATE CASE VIEW

B

REVISION INFORMATION

12 • Lineup Assembly

Содержание 3RMCC30WA

Страница 2: ......

Страница 4: ......

Страница 36: ...ELECTRICAL LOW TEMP Figure 26 Electric Defrost 30 24 Wiring 32 Electrical Low Temp...

Страница 37: ...ELECTRICAL LOW TEMP CONT Figure 27 Hot Gas Wiring Electrical Low Temp 33...

Страница 38: ...ELECTRICAL LOW TEMP CONT Figure 28 Single Point Wiring 34 Electrical Low Temp...

Страница 39: ...ELECTRICAL LOW TEMP CONT Figure 29 Master Satellite Wiring Electrical Low Temp 35...

Страница 40: ...ELECTRICAL MEDIUM TEMP Figure 30 RVCC30 and RMCC24 Wiring Diagram 36 Electrical Medium Temp...

Страница 41: ...ELECTRICAL MEDIUM TEMP CONT Figure 31 Single Point Wiring Electrical Medium Temp 37...

Страница 42: ...ELECTRICAL MEDIUM TEMP CONT Figure 32 Master Satellite Wiring 38 Electrical Medium Temp...