- 4-20 -

MAINTENANCE/INSPECTION PROCEDURE

2. Required Maintenance

The recording density of a VCR(VCP) is much higher than

that of an audio tape recorder. VCR(VCP) components must

be very precise, at tolerances of 1/1000mm, to ensure com-

patibility with the other VCRs. If any of these components are

worn or dirty, the symptoms will be the same as if the part is

defective. To ensure a good picture, periodic inspection and

maintenance, including replacement of worn out parts and

lubrication, is necessary.

3. Scheduled Maintenance

Schedules for maintenance and inspection are not fixed

because they vary greatly according to the way in which the

customer uses the VCR(VCP), and the environment in which

the VCR(VCP) is used.

But, in general home use, a good picture will be maintained

if inspection and maintenance is made every 1,000 hours.

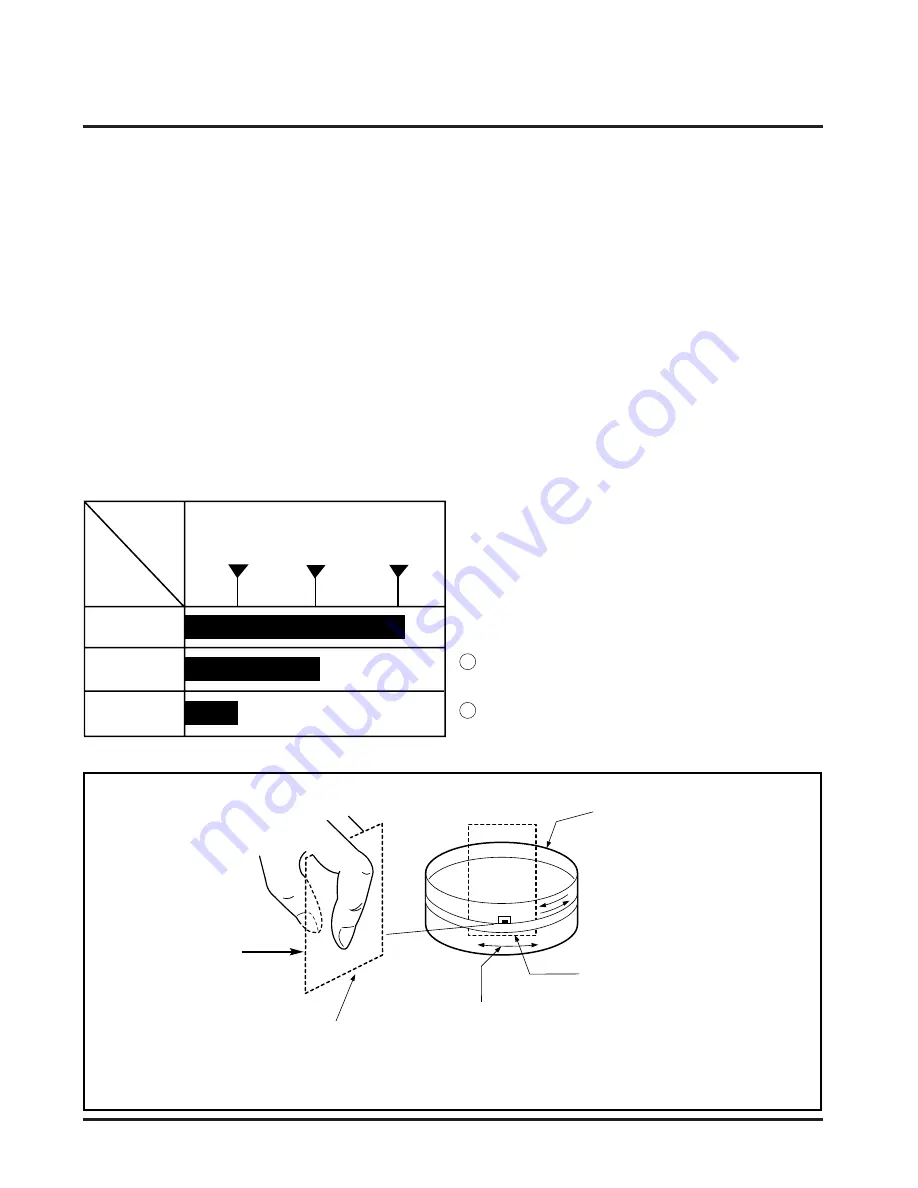

The table below shows the relation between time used and

inspection period.

Table 1

4. Supplies Required for Inspection and

Maintence

(1) Grease : Kanto G-311G (Blue) or equivalent

(2) Isopropyl Alcohol or equivalent

(3) Cleaning Patches

(4) Grease : Kanto G-381(Yellow)

5. Maintenance Procedure

5-1) Cleaning

(1) Cleaning video head

First use a cleaning tape. If the dirt on the head is too

stubborn to remove by tape, use the cleaning patch. Coat

the cleaning patch with Isopropyl Alcohol. Touch the

cleaning patch to the head tip and gently turn the

head(rotating cylinder) right and left.

(Do not move the cleaning patch vertically. Make sure

that only the buckskin on the cleaning patch comes into

contact with the head. Otherwise, the head may be dam-

aged.)

Thoroughly dry the head. Then run the test tape. If lso-

propyl Alcohol remains on the video head, the tape may

be damaged when it comes into contact with the head

surface.

(2) Clean the tape transport system and drive system, etc, by

wiping with a cleaning patch wetted with Isopropyl

Alcohol.

NOTES:

1

It is the tape transport system which comes into contact

with the running tape. The drive system consists of those

parts which moves the tape.

2

Make sure that during cleaning you do not touch the tape

transport system with excessive force that would cause

deformation or damage to the system.

About 1

year

One hour

Two hours

Three hours

When

inspection is

necessary

Average

hours used

per day

About 18

months

About 3

years

Fig. C-9-4

Drum

(Rotating Cylinder)

Head Tip

Coat With Isopropyl Alcohol

Touch this section of cleaning

patch to the head tip and gently

turn the Drum (Rotating Cylinder)

Cleaning Patch

Содержание XBS341 Series

Страница 1: ...SERVICE MANUAL MODELS XBS341...

Страница 10: ...2 1 SECTION 2 AUDIO PART...

Страница 12: ...3 2 VCR ELECTRICAL TROULBESHOOTING...

Страница 13: ...3 3...

Страница 27: ...SECTION 4 MECHANSIM OF VCR PART...

Страница 39: ...4 12...

Страница 41: ...4 14...

Страница 51: ...4 24...

Страница 58: ...5 1 DVD ELECTRICAL TROUBLESHOOTING 1 Test debug flow SECTION 5 DVD PART...

Страница 59: ...5 2...

Страница 60: ...5 3...

Страница 61: ...5 4...

Страница 62: ...5 5...

Страница 63: ...5 6...

Страница 65: ...5 8 3 RS232 waveform during procedure Downloading 4 Flash R W enable signal during download Downloading...

Страница 66: ...5 9 2 SDRAM CLOCK 1 MT1379 main clock is at 27MHz X501 3 TRAY OPEN CLOSE SIGNAL 1 Tray open close waveform...

Страница 67: ...5 10 2 Tray close waveform 3 Tray open waveform...

Страница 68: ...5 11 4 SLED CONTROL RELATED SIGNAL NO DISC CONDITION 5 LENS CONTROL RELATED SIGNAL NO DISC CONDITION...

Страница 69: ...5 12 6 LASER POWER CONTROL RELATED SIGNAL NO DISC CONDITION 7 DISC TYPE JUDGEMENT WAVEFORM...

Страница 70: ...5 13...

Страница 71: ...5 14 8 FOCUS ON WAVEFORM...

Страница 72: ...5 15 9 SPINDLE CONTROL WAVEFORM NO DISC CONDITION...

Страница 73: ...5 16 10 TRACKING CONTROL RELATED SIGNAL System checking...

Страница 74: ...5 17 11 RF WAVEFORM 12 MT1379 AUDIO OPTICAL AND COAXIAL OUTPUT ASPDIF...

Страница 75: ...5 18 13 MT1379 VIDEO OUTPUT WAVEFORM 1 Full colorbar signal CVBS 2 Y...

Страница 76: ...5 19 3 C 14 AUDIO OUTPUT FORM AUDIO DAC 1 Audio related Signal...

Страница 77: ...5 20 MEMO...

Страница 80: ...2 2 2 3 BLOCK DIAGRAM...

Страница 81: ...2 4 2 5 AUDIO SHEMATIC DIAGRAMS U COM SCHEMATIC DIAGRAM...

Страница 82: ...2 6 2 7 FUNCTION POWER SCHEMATIC DIAGRAM...

Страница 83: ...2 8 2 9 MAIN AMP SCHEMATIC DIAGRAM...

Страница 84: ...2 10 2 11 WIRING DIAGRAM...

Страница 86: ...2 14 2 15 PRINTED CIRCUIT DIAGRAM MAINAMP FRONT P C BOARD SOLDER SIDE...

Страница 87: ...2 16 2 17 MAINAMP FRONT P C BOARD COMPONENT SIDE...

Страница 88: ...2 18 2 19 FUNCTION POWER P C BOARD SOLDER SIDE...

Страница 89: ...2 20 2 21 FUNCTION POWER P C BOARD COMPONENT SIDE...

Страница 90: ...3 17 3 18 VCR SHEMATIC DIAGRAMS SYSTEM SCHEMATIC DIAGRAM...

Страница 91: ...3 19 3 20 A AUDIO V VIDEO SCHEMATIC DIAGRAM...

Страница 93: ...3 23 3 24 HIFI TUNER SCHEMATIC DIAGRAM...

Страница 94: ...3 25 3 26 A V JACK SCART SCHEMATIC DIAGRAM...

Страница 96: ...3 29 3 30 PRINTED CIRCUIT DIAGRAMS TUNER P C BOARD...

Страница 97: ...3 31 3 32 VCR P C BOARD...

Страница 98: ...3 33 3 34 VCR P C BOARD...

Страница 99: ...5 22 5 21 DVD PART SCHEMATIC DIAGRAMS MPEG SCHEMATIC DIAGRAM...

Страница 100: ...5 23 5 24 SERVO SCHEMATIC DIAGRAM...

Страница 101: ...5 25 5 26 AUDIO SCHEMATIC DIAGRAM...

Страница 102: ...5 27 5 28 INTERFACE SCHEMATIC DIAGRAM...

Страница 103: ...5 29 5 30 VOLTAGE SHEET IC TR...

Страница 104: ...5 31 5 32 PRINTED CIRCUIT DIAGRAM DVD P C BOARD SOLDER SIDE...

Страница 105: ...5 33 5 34 DVD P C BOARD COMPONENT SIDE...

Страница 107: ...MEMO MEMO...

Страница 109: ...MEMO MEMO...

Страница 115: ......