10

11

window will have to be cleaned off. After installing the o-ring, ensure it is

clean. If necessary, wipe clean with a lens tissue.

Locate the o-ring lubricant included with the new sensor cap. Apply a thin

6.

coat of o-ring lubricant to the installed o-ring. After application, there

should be a thin coat of o-ring lubricant on the o-ring only. Remove any

excess o-ring lubricant from the o-ring and/or probe with a lens tissue.

Clean the clear surface of the optical DO sensor window (figure 1) with a

7.

lens cleaning tissue.

Remove the new sensor cap from its hydrated container and dry the inside

8.

cavity of the sensor cap with lens tissue. Make sure that the cavity is

completely dry and clean before proceeding with the installation. Using a

clockwise motion, thread the new sensor cap onto the probe assembly until

it is finger-tight. The o-ring should be compressed between the sensor cap

and probe. Do not over-tighten the sensor cap and do not use any tools for

the installation process.

Clean the stir paddle and then reinstall it on the probe by pushing it straight

9.

into place.

Store the sensor in a BOD bottle with a small amount of water (approximately

10.

40 ml).

Follow the procedures below for configuring the ProODO instrument for

11.

the new Sensor Cap’s coefficients.

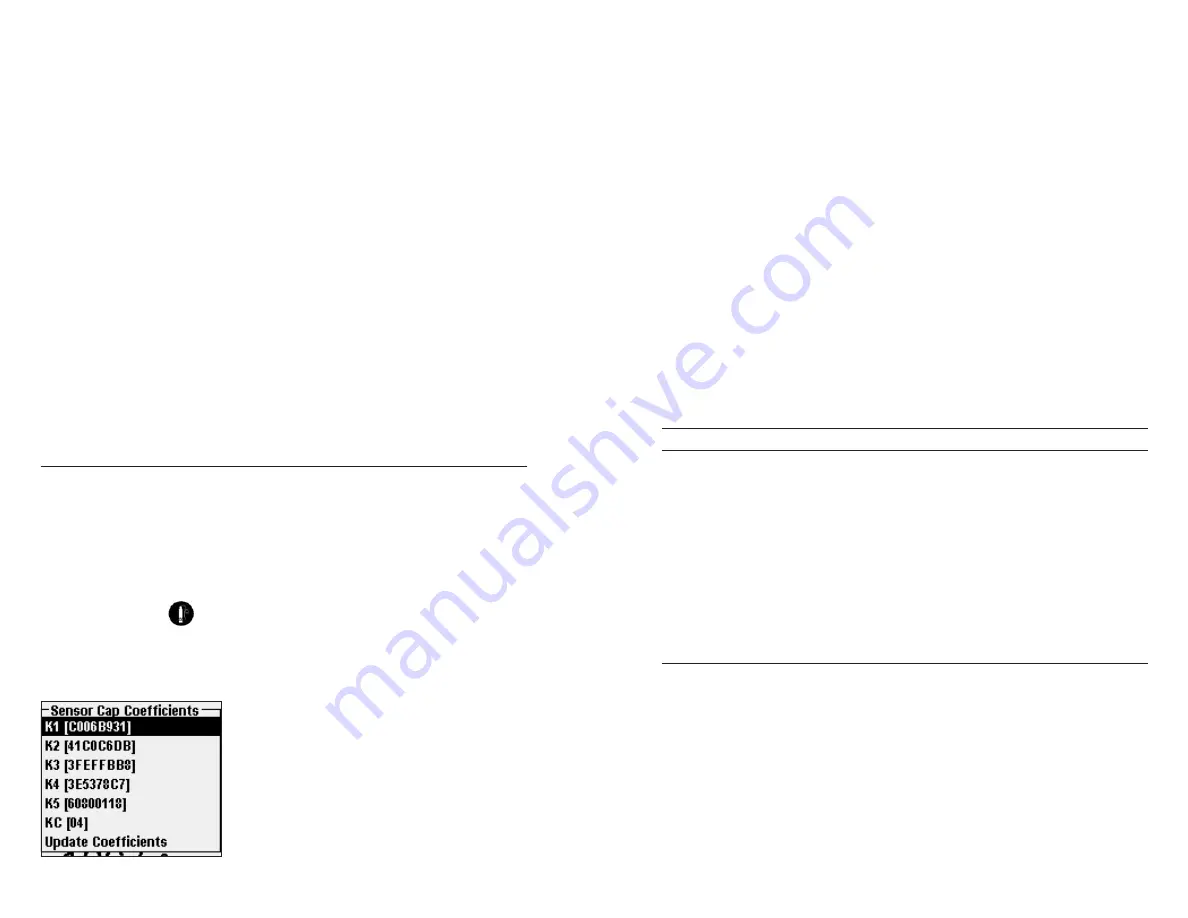

Configuring ProODO Instrument for new Sensor Cap

After installing a new Sensor Cap, connect the probe/cable assembly to the

ProODO instrument and turn the instrument on. Locate the Calibration Code

label at the top of the Sensor Cap instruction sheet and note the six numbers

which are listed as k1 through k5 and kC. These six numbers contain the

calibration code specific to the sensor cap that was just installed. Follow the

instructions below to enter the new calibration coefficients into your ProODO

instrument.

Press the

1.

Probe

on the ProODO instrument, highlight

DO

, and press

enter.

Highlight

2.

Sensor Cap

and press enter.

Highlight

3.

Sensor Cap Coefficients

and press enter.

k1 will be highlighted. Press enter to access

4.

the numeric entry screen. Enter the new k1

coefficient from the Calibration Code label.

After the Calibration Code has been entered

correctly, press enter to confirm.

Highlight k2 through kC in turn and use the

5.

numeric entry screen to enter the corresponding

new coefficient from the Calibration Code label

as described in step 4. Press enter after each entry and then proceed to the

next k selection.

After all the new coefficients have been entered, highlight

6.

Update

Coefficients

and press enter.

A message will appear warning that you will be overwriting the current

7.

sensor cap coefficients and you should confirm that you wish to carry out

this action. Highlight

Yes

and press enter to confirm the new coefficients.

After updating the Coefficients, the Serial # in the Sensor Cap menu will be

updated automatically based on your entries.

If an error is made in entering the Sensor Cap Coefficients, the instrument

will block the update and an error message will appear on the display. If you

see this error message, re-enter the coefficients checking them carefully for

correct transcription from the Calibration Code label prior to selecting

Update

Coefficients

. If you continue to get an error message after several entry

attempts, contact YSI Technical Support for assistance.

After entering the new Sensor Cap coefficients, perform a 1-point DO

calibration.

REHYDRATING THE SENSOR CAP

The Sensor Cap must remain in a moist environment for proper operation; see

Sensor Storage

for storage recommendations. If you inadvertently leave your

sensor exposed to ambient air for a period of more than approximately 8 hours

it may dry out. If the sensor cap is allowed to dry out, it is likely to drift slightly

at the beginning of your next study unless it is rehydrated. If the cap dries out,

you can rehydrate it by soaking the probe tip with the sensor cap installed in

warm (room temperature) tap water for 24 hours. After rehydration is complete,

perform a 1-point DO calibration and be sure to store the probe in a moist

environment.

sensOr maintenance - temperatUre

You must keep the temperature portion of the sensor free of build up. Other

than that, the sensor requires no maintenance. A soft bristle brush can be used

to scrub the temperature sensor if needed. While cleaning, be sure to only scrub

the temperature sensor and not the sensor cap. The sensor cap will be damaged

if cleaned with anything abrasive.

Содержание WE KNOW ProOBOD

Страница 1: ...USER MANUAL ...