FORM 155.32-ICOM2.EN.UL

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

29

USE OF OIL

If an oil leak is present do not operate the machine until the leak is repaired and stopped.

Use only the fuel specified on the unit name plate.

Inspect the exhaust duct periodically to check for gas leaks.

If black and white smoke is produced, stop the machine and contact your local Johnson

Controls Service Office for assistance.

Do not block the outer cover suction port or exhaust port. This can cause oxygen

starvation.

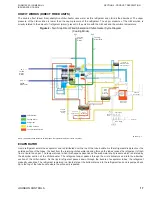

VIBRATION AND ISOLATION DETAILS

Before installing the unit, fit rubber vibration isolators to the unit base as shown below. Use

liners to adjust the levelness of the unit. For unit dimension, see

and

.

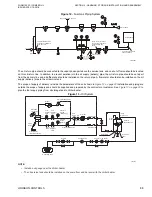

RUPTURE DISK AND RELIEF PIPING

For YHAU units, this device is a metallic, one time use, rupture disk burst rated at 7.0

PSIG, +/- 2.0 PSI (48.2 kPa, +/- 13.8 kPa).

The size of the rupture disc will depend on

the chiller capacity.

The rupture disk will protect the chiller’s integrity should there ever be a tube rupture or in

the very unlikely event that the unit’s refrigerant vapor pressure gets too high. Unlike vapor

compression cooling machines that relieve refrigerant vapor, if the rupture disk bursts,

absorption machines could expel a vapor and a liquid.

WARNING: During service and maintenance work, be sure to turn OFF the main circuit

breaker (MCB1) and follow all required Lockout and/or Tagout procedures. Close the

main valve of the fuel gas line. Failure to close the gas line may cause electric shock

and burn.

NOTE: The ANSI/ASHRAE 15-2001 safety standard code was recently revised to include

absorption chiller relief devices. Please read and follow these instructions closely to en-

sure the chiller installation is compliant to the revised code.

LD20186

Nut

Washer

Foundation Bolt

Base

Rubber Vibration

Isolator

Sole Plate

Nut

Washer

Filling with Mortar

Foundation Bolt

Rubber Vibration

Isolator

Sole Plate

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...