FORM 155.32-ICOM2.EN.UL

SECTION 7 – MAINTENANCE

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

121

SECTION 7 – MAINTENANCE

When inspecting and maintaining the absorption chiller-heater, observe the following items:

• Never splash water over the electrical parts installed to the control panel and absorp-

tion chiller-heater.

• Do not change the set values of the control devices and safety switches without per-

mission.

• Do not turn the internal cycle control valve of the absorption chiller-heater without per-

mission.

• When replacing the oil in the vacuum pump, be sure to turn OFF the main circuit

breaker (MCB1) in the control panel.

EXHAUST DUCT INSPECTION

Inspect the exhaust duct periodically to check for a gas leak.

VALVE INSPECTION

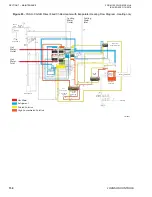

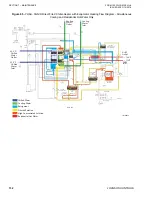

The chiller-heater is equipped with a refrigerant manual blow valve (V8) that blows

refrigerant from the refrigerant tank to the absorber directly. See

,

.

The valve must not be tampered with or have its settings altered. Daily maintenance or

inspection is the only reason to touch the valve.

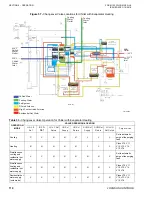

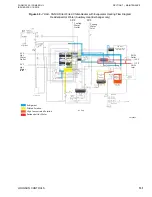

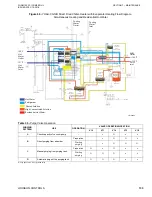

SOLENOID VALVES

The absorption chiller-heater is equipped with the following solenoid valves.

Table 35 -

Solenoid Valves

WARNING: If you smell gas, do not operate the machine or manipulate the switches

until the gas smell vanishes.

WARNING: During service and maintenance work, be sure to turn OFF the main cir-

cuit breaker (MCB1) and fully close the main valve of fuel gas line. If not, it may cause

electric shock and burn.

CAUTION: Contact your local Johnson Controls Service Office for inspection and

maintenance of the unit. Improper inspection and maintenance can cause a mechani-

cal malfunction or injury.

SOLENOID VALVE NAME

SYMBOL

FUNCTION

Purge solenoid valve (1)

SV1

Close vacuum pump piping

Purge solenoid valve (2)

SV2

Refrigerant blow solenoid valve

SV3

Close automatic refrigerant blow piping

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...