FORM 155.32-ICOM2.EN.UL

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

27

PRECAUTIONS FOR USE

Ventilate the storage area as much as possible to keep the humidity low. Avoid storing the

unit in an area where the humidity is 95%RH or higher, and the temperature is 40°C

(104°F) or higher. For more information about long term-storage, refer to

Long-term

Storage Requirements (Form 50.20-NM1)

and

Long-term Storage Checklist (Form 50.20-

CL4)

.

Silica gel can be used on a temporary basis to dehumidify the control panel, but should be

removed once the moisture is absorbed. Otherwise, the silica gel can corrode the electrical

parts of the control panel.

Do not allow negative pressure or any devices that create negative pressure to operate in

the area around the chiller-heater. This may cause incomplete combustion, resulting in gas

inhalation and hypoxia.

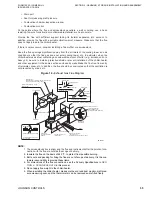

To prevent injuries, do not put a finger, a rod, or anything else into any rotary parts of the

vacuum pump.

A caution label for a rotating object is pasted around the belt cover of the vacuum pump.

When replacing the oil in the vacuum pump, belt, or performing maintenance work, stop the

chiller-heater and be sure to turn off the main circuit breaker (MCB1) and lockout/tagout the

unit. If this is not done, the vacuum pump could start abruptly and cause injury or damage

to the unit.

Do not place any heavy objects on the machine or its control panel; it may fall and cause

injury.

Do not climb up the unit without safety harnessing.

Contact your local Johnson Controls service office for inspection and maintenance of the

unit. Improper inspection and maintenance can not only cause a machine malfunction but

also injury.

Keep the chilled/hot water and cooling water under the maximum usage pressure. If they

exceed the maximum usage pressure, they may spout or leak and may cause an electric

leak and injury.

Do not change the set values of the safety devices and protective devices. Operation with

incorrect set values can cause a malfunction.

In the event that the circuit breaker or disconnect switch is activated, eliminate the cause of

the problem before restarting the unit. See

.

The shut off valve for the pressure release valve must constantly remain open. It may only

be closed when servicing the pressure relief valve. The unit must never be operated with

this shut off valve closed.

Verify the main valve for the fuel gas is closed before servicing the chiller-heater. Only a

Johnson Controls service representative can modify the main gas valve or any of the fuel

control devices after the chiller-heater has been serviced. Operation of the chiller-heater by

an inexperienced person could result in incomplete combustion, fire, or injury.

Do not touch any part or component displaying a high temperature caution label while the

machine is in operation. This includes the control panel, solution pump, vacuum pump and

any piping entering or exiting the solution and vacuum pump.

Periodically inspect the strainers to prevent clogging and incomplete combustion.

Wear protective gloves and goggles when operating the chiller-heater.

Do not operate the machine with panel doors open or removed. Exposure to rainwater or

wind pressure can damage the electrical parts of the unit or cause leakage.

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...