FORM 155.32-ICOM2.EN.UL

SECTION 3 - HANDLING, STORAGE, INSTALLATION AND REASSEMBLY

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

23

3. Periodic Inspection and Maintenance

a. Inspect the machine weekly for damage.

b. Check the machine compound gauge daily to verify there is no decline in vacuum

and record the vacuum value

(

-760 to -38 mmHg (G) or 0 to 722mmHg (ABS). If

the vacuum is below the low limit, contact your nearest authorized Johnson Con-

trols Service Center immediately.

c.

If the vacuum has dropped as a result of improper machine operation, contact your

nearest authorized Johnson Controls Service Center immediately.

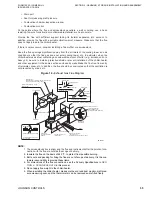

HOISTING THE MACHINE

When hoisting the machine, attach a shackle to each of the four eye plates and lift the

machine using care that the angle formed by the wire is within 60° as shown in the figure

below.

Use care not to apply shock to the machine. The machine is a high-vacuum vessel

containing a corrosive solution. Use diligence in protecting the machine as repair is labor

intensive and costly.

Be sure to lift the machine horizontally. If the machine is inclined, the solution and

refrigerant inside will shift producing an offset load. This can cause damage to the machine

and pose a risk to the machine installer or persons moving the unit.

Figure 3 -

Hoisting Procedures (4-point Listing)

NOTE: Once the Silica gel absorbs moisture it can corrode electrical parts. It is import-

ant to replace this gel every six months. Always avoid storing the machine in areas

where the humidity is 95%RH or higher and the temperature is

104 °F (40 °C) or higher.

CAUTION: Use care that foreign matter does not enter the drain valve and air vent valve

in the water chamber casing. Keep these valves fully open while the machine is in stor-

age.

LD22931

THIS ANGLE MUST BE WITHIN 60 DEGREES

4.3M OR MORE

EYE PLATE (EA)

EYE PLATE (LG)

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...