SECTION 7 – MAINTENANCE

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

154

JOHNSON CONTROLS

Figure 71 -

Wet Storage During Heating Operation Period

Work Procedure

1. If the quality of the remaining cooling water is deteriorated, drain all the cooling water

from the absorber and the c

ondenser

.

2. Flow clean water from a higher location than the chiller-heater. Then feed the clean

water continuously and clean the tubes well.

3. Fill the absorber and the condenser with clean water.

4. Circulate the clean water with the cooling water pump for 30 minutes to 1 hour.

5. Drain all of the cooling water from the absorber and er.

6. Fill the absorber and condenser with clean water.

7. Keep this condition during heating operation period.

LD27455

3

3

3

Tapping for

7

7

7

7

7

7

7

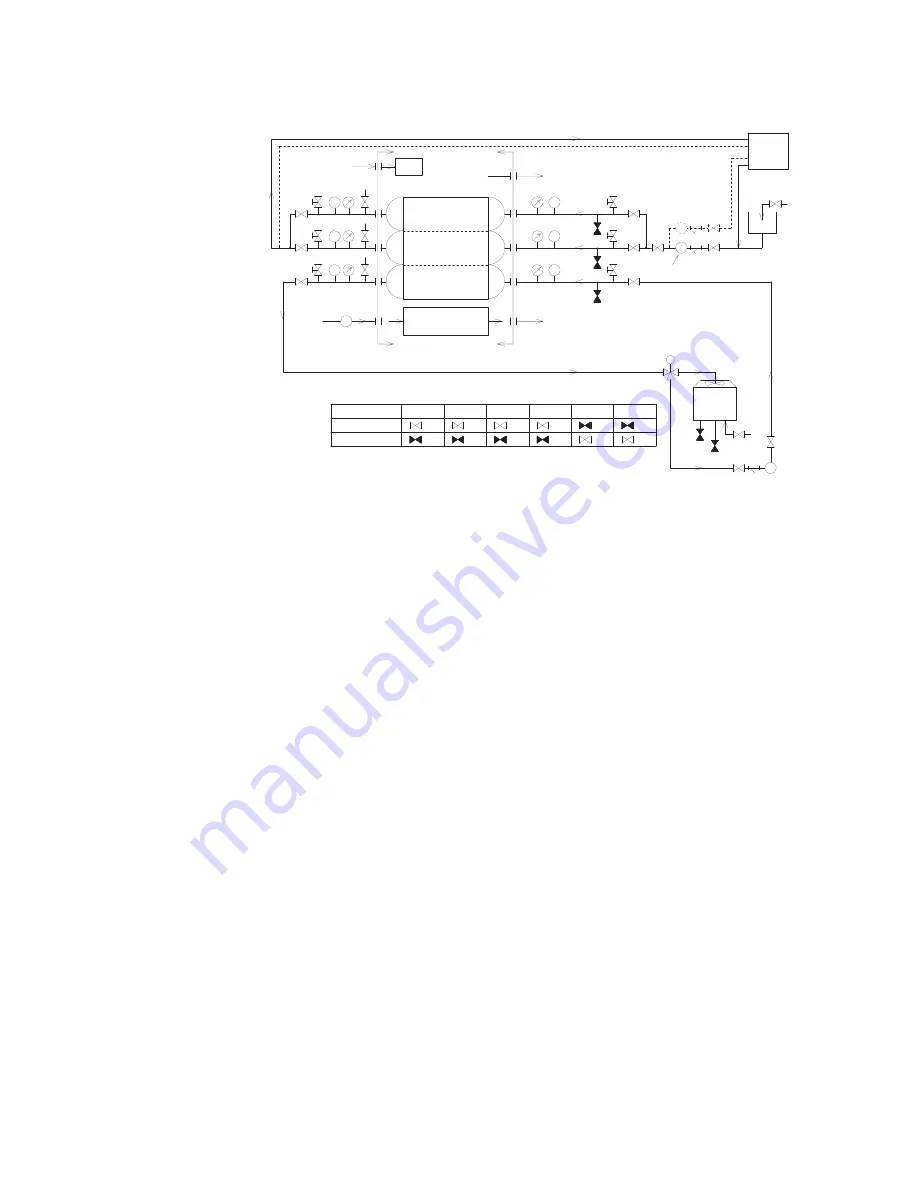

Valve Setting

:NXKK=G_<GR\K

=OZNOT9IUVKUL*KRO\KX_

.OMN:KSVKXGZ[XK

-KTKXGZUX

5[ZYOJK9IUVKUL*KRO\KX_

8KVRGIKSKTZ=GZ

*XGOT<KTZ

'HYUXVZOUT

)NORRKXNKGZKX

INKSOIGRIRKGTOTM

/TYZGRRZNKV[SVGZZNKNOMNVXKYY[XK

YOJKULZNK'HYUXVZOUTINORRKXNKGZKX

)NORRKJ=GZKX6[SV

'HYUXHKX)UTJKTYKX

LUX)UUROTM]GZKX

+\GVUXGZUX

LUX)NOORKJ]GZKX

'JJOZOUTGR.KGZ+^INGTMKX

LUXNKGZOTM.=

,R[K-GY

)UUROTM

:U]KX

(RU]

\GR\K

*XGOT

<KTZ

8KVRGIKSKTZ

=GZKX

+^VGTYOUT

:GTQ

)OXI[RGZOTM

.KGJKX

6U]KXY[VVR_OTYZX[SKTZG

ZOUT:KRKVNUTKROTKLUX

SUTOZUXOTM

)UTZXUR

6GTKR

*XGOTLXUS

)NORRKXNKGZKX

GTJYGLKZ_\GR\K

*XGOTGMKKW[OVSKTZ

:GVVOTMLUXINKSOIGR

IRKGTOTM

'OX\KTZ

)UTZXUR6GTKR

,RU]

3KZKX

,[KR

5[ZYOJK9IUVKUL*KRO\KX_

)UUROTM=GZKX6[S

5VKT

5VKT

5VKT

5VKT

)RUYK

)RUYK

)RUYK

)RUYK

)RUYK

)RUYK

5VKT

5VKT

)RGYYOLOIGZOUT

*[XOTM.KGZOTM

*[XOTM)UUROTM

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...