SECTION 7 – MAINTENANCE

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

128

JOHNSON CONTROLS

MANUAL METHOD TO PURGE NON-CONDENSABLE GAS FROM THE

PURGE TANK

While the absorption chiller-heater operates, non-condensable gas collects in the purging

tank. You can purge those gases manually using the following procedure.

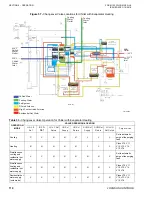

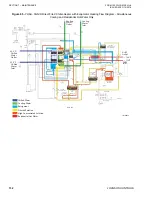

1. Set the valves according to Pattern C, see

.

2. Press the Purge Mode

Manual

button.

3. Press the Manual Purge

ON

button. The vacuum pump starts. The solenoid valves

SV1 and SV2 open.

4. After 1-2 minutes, confirm that the vacuum gauge indicates approximately1 kPa.

5. Verify that valve V10 is open.

6. Reading the vacuum gauge, gradually open valve V11.

7. The manual purge procedure is complete when the pressure reaches 3 kPa and be-

low on the vacuum gauge.

8. Close valve V11.

9. Press the Purge Pump

OFF

button. The vacuum pump stops. For information on how

to set up an automatic purge,

Automatic Method to Purge Non-condensable Gas

from the Purge Tank on page 128

.

AUTOMATIC METHOD TO PURGE NON-CONDENSABLE GAS FROM

THE PURGE TANK

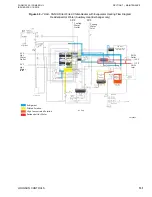

This chiller-heater has an automatic purge system. The vacuum pump starts and stops by

detecting the pressure inside the purge tank.

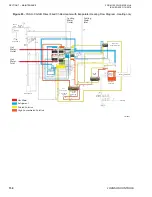

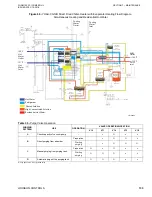

1. Set the valve according to Pattern D.

Purge Valve Operation on page 133

.

2. Press the Manual Purge

OFF

button.

3. Press the Purge Mode

Auto

button.

4. The purge solenoid valves automatically open and close.

During the automatic purge operation, the vacuum pump starts when the purging tank

pressure increases to 7 kPa abs and stops when it decreases to 3 kPa abs.

WARNING: When you replace the oil in the vacuum pump or belt or perform

maintenance work while the absorption chiller-heater is running, be sure to turn off the

circuit breaker of the vacuum pump in the control panel. If not, the vacuum pump could

start abruptly and cause injury.

Содержание YHAU-CGH

Страница 14: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 14 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 38: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 38 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 55: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 JOHNSON CONTROLS 55 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 57: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 57 LD27463...

Страница 59: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 59 LD27465...

Страница 61: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 61 LD27471...

Страница 63: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 63...

Страница 65: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 65 LD27477...

Страница 67: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 67 LD27479...

Страница 69: ...FORM 155 32 ICOM2 EN UL SECTION 4 TECHNICAL DATA ISSUE DATE 1 10 2018 JOHNSON CONTROLS 69 LD27475...

Страница 160: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 160 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 170: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 170 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 172: ...FORM 155 32 ICOM2 EN UL ISSUE DATE 1 10 2018 172 JOHNSON CONTROLS THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 181: ...FORM 155 32 ICOM2 EN UL APPENDIX 1 CHECKLIST ISSUE DATE 1 10 2018 JOHNSON CONTROLS 181 NOTES...