5604542-UIM-B-0419

6

Johnson Controls Ducted Systems

12. Release the refrigerant charge into the system. Open the liquid line

valve first, then the vapor line valve by removing the plunger cap

and turning the valve counter-clockwise using hex head wrenches.

Valves are fully open when the valve stem is touching the cham-

fered retaining wall at the top of the valve. If the service valve is a

ball type valve, use an adjustable end wrench to turn the valve stem

one quarter turn counter-clockwise to open it. DO NOT overturn or

the valve stem may break or become damaged. See PRECAU-

TIONS DURING BRAZING SERVICE VALVE.

13. Replace service valve cap finger tight, then tighten an additional 1/

12 turn (1/2 hex flat). Cap must be replaced to prevent leaks.

14. See “System Charge” section for checking and recording system

charge. See Section VI.

SECTION IV: INDOOR EXPANSION DEVICE

THERMOSTATIC EXPANSION VALVE

(

TXV)

INSTALLATION

The following are the basic steps for installation. For detailed instruc-

tions, refer to the Installation Instructions accompanying the TXV kit.

Install TXV kit as follows:

1.

Relieve the holding charge by depressing Schrader core on the

suction manifold stub out.

2.

After holding charge is completely discharged, loosen and remove

the Schrader core.

3.

Place a backup wrench on distributor, loosen and remove brass

distributor nut. Retain brass nut for use on liquid line. Keep Teflon

washer in place and discard clear disk.

4.

Install the thermal expansion valve to the distributor assembly with

supplied fittings. Ensure Teflon washer is seated in distributor.

Hand tighten and turn an additional 1/4 turn to seal. Do not over

tighten fittings. See Figure 6.

5.

Slide the nut removed in step 3 over the supplied liquid line. Place

supplied Teflon washer from TXV kit in place on TXV, and install liq-

uid line to the top of the thermal expansion valve. Adjust assembly

so liquid line aligns with hole in access panel. Hand tighten the liq-

uid line, and apply an additional 1/4 turn to seal.

6.

Install the TXV equalizer line onto the vapor line by hand tightening

the 1/4” SAE coupling nut to the equalizer fitting, and apply an

additional 1/3 turn to seal. See Figure 7.

7.

Pass the TXV temperature sensing bulb through the suction line

split grommet in the access panel.

WARNING

Never attempt to repair any brazed connections while the system is

under pressure. Personal injury could result.

CAUTION

Outdoor unit model numbers ending with an “H” have a factory

installed hard start kit which is required when a TXV is installed on the

indoor unit. Outdoor unit model numbers with no “H” ending do not

require a hard start kit unless a TXV is being installed on the indoor

unit or unless local regulations dictate it. The Tabular Data Sheet

which comes with the unit specifies whether or not a hard start kit is

required. When a TXV Kit is needed, it should be ordered from

Source 1.

IMPORTANT

Refer to the Technical Guide for the unit to determine the proper TXV

kit to be used on this product.

CAUTION

Do not over-torque. Do not use slip joint pliers. This will distort the

aluminum distributor and the brass fitting (potentially causing leaks).

!

!

!

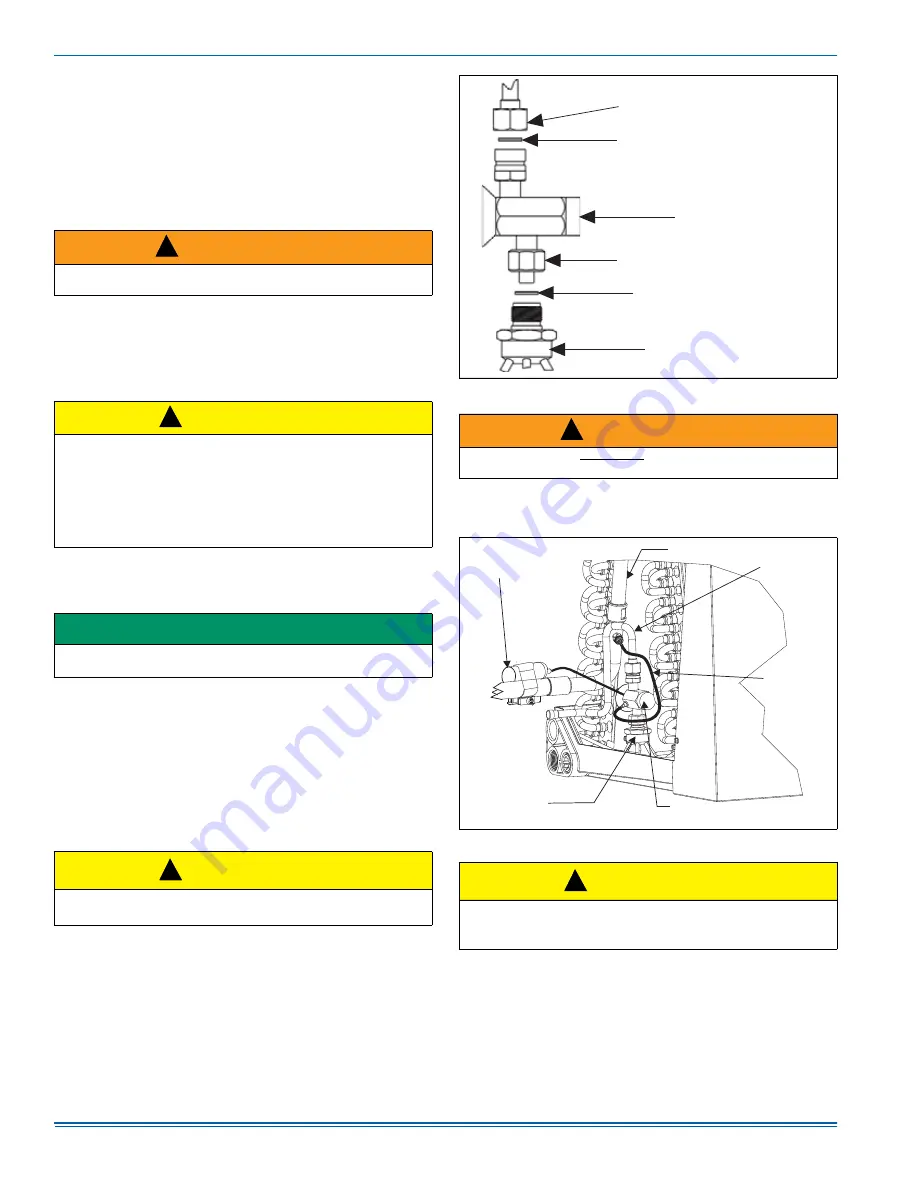

FIGURE 6:

TXV Installation

WARNING

Schrader valve core

MUST NOT

be installed with TXV installation.

Poor system performance or system failure could result.

FIGURE 7:

TXV Bulb and Equalizer Line Installations

CAUTION

In all cases, mount the TXV bulb after vapor line is brazed and has

had sufficient time to cool. Failure to use suction line grommet may

result in premature TXV failure.

T

X

V

/

D

I

STR

IB

UTOR

COUP

LING

LI

QU

I

D

LIN

E

/

T

X

V

COUP

LING

TE

FL

O

N W

AS

H

ER

T

X

V

TE

FL

O

N W

AS

H

ER

D

I

STR

IB

UTOR

A

0281-001

!

T

X

V

B

U

LB

(Wrap with

insulation.)

VAPOR

LIN

E

LI

QU

I

D

LIN

E

TV

X

EQUA

LIZ

ER

LIN

E

T

H

ER

M

A

L

E

X

PA

N

S

I

O

N

VA

L

VE

(

T

X

V

)

D

I

STR

IB

UTOR

B

OD

Y

A

0279-002

!