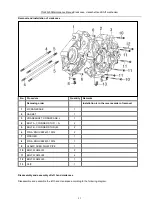

YG48Q-5AMaintenance ManualCrankcase, crankshaft and Shift mechanism

104

Check

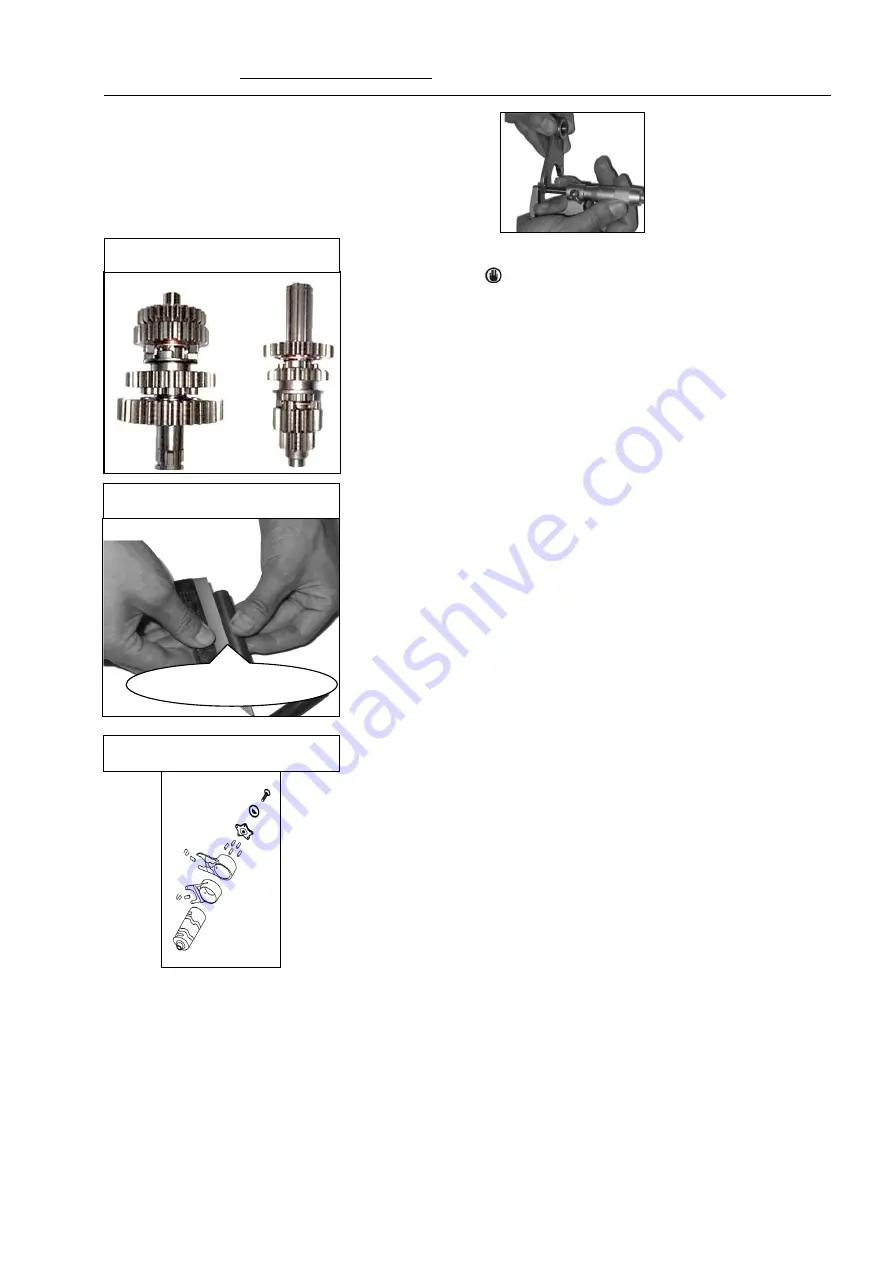

Check the driving/driven shaft gears for serious abrasion

and pit corrosion; check whether the shift fork is bent and

whether the gearshift drum guiding slot is damaged.

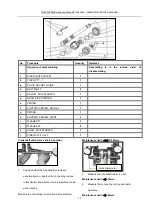

Measure the shift fork claw thickness.

Maintenance limit:

≥

4.86mm.

Warning

Thread retaining adhesive LOCTITE243 must be

applied to the rotor retaining nut M12 while

assembling, with the tightening torque being 45N.m.

Driving/driven shaft inspection

Gearshift drum inspection

Shift fork shaft inspection

Outside micrometer

Содержание YG48Q-5A

Страница 38: ...YG48Q 5AMaintenance ManualFuel system 41 4 Fuel system...

Страница 42: ...YG48Q 5A Maintenance ManualRemoval and installation of engine 46 5 Removal and installation of engine...

Страница 92: ...YG48Q 5AMaintenance ManualFrame and exhaust system 105 10 Frame and exhaust system...

Страница 108: ...YG48Q 5A Maintenance ManualRear wheel and rear suspension device 121 12 Rear wheel and rear suspension device...

Страница 123: ...YG48Q 5A Maintenance ManualIllumination signal system 136 Circuit schematic drawing...

Страница 126: ...YG48Q 5A Maintenance ManualIllumination signal system 139...

Страница 133: ...YG48Q 5A Maintenance ManualEngine management system 146 Major parts and components...

Страница 134: ...YG48Q 5A Maintenance ManualEngine management system 147...

Страница 144: ...YG48Q 5A Maintenance ManualElectrical System Diagram 157 19 Electrical System Diagram...