YG48Q-5A Maintenance Manual

Inspection and adjustment

27

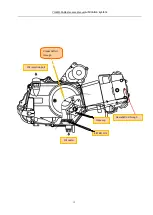

Timing phase

It shall be carried out when the vehicle is new or there is

any question about the timing phase.

Remove the cylinder head cover

Turn the crankshaft pulley Counterclockwise to align the

scale line “I” with the indication mark “ ” on the front-left

cover.

When the piston is at the upper dead point, the scale line

on the camshaft is at the same level with the.

Notice

At this point, the piston must be at the upper dead

point of the compression stroke other than that of the

exhaust stroke.

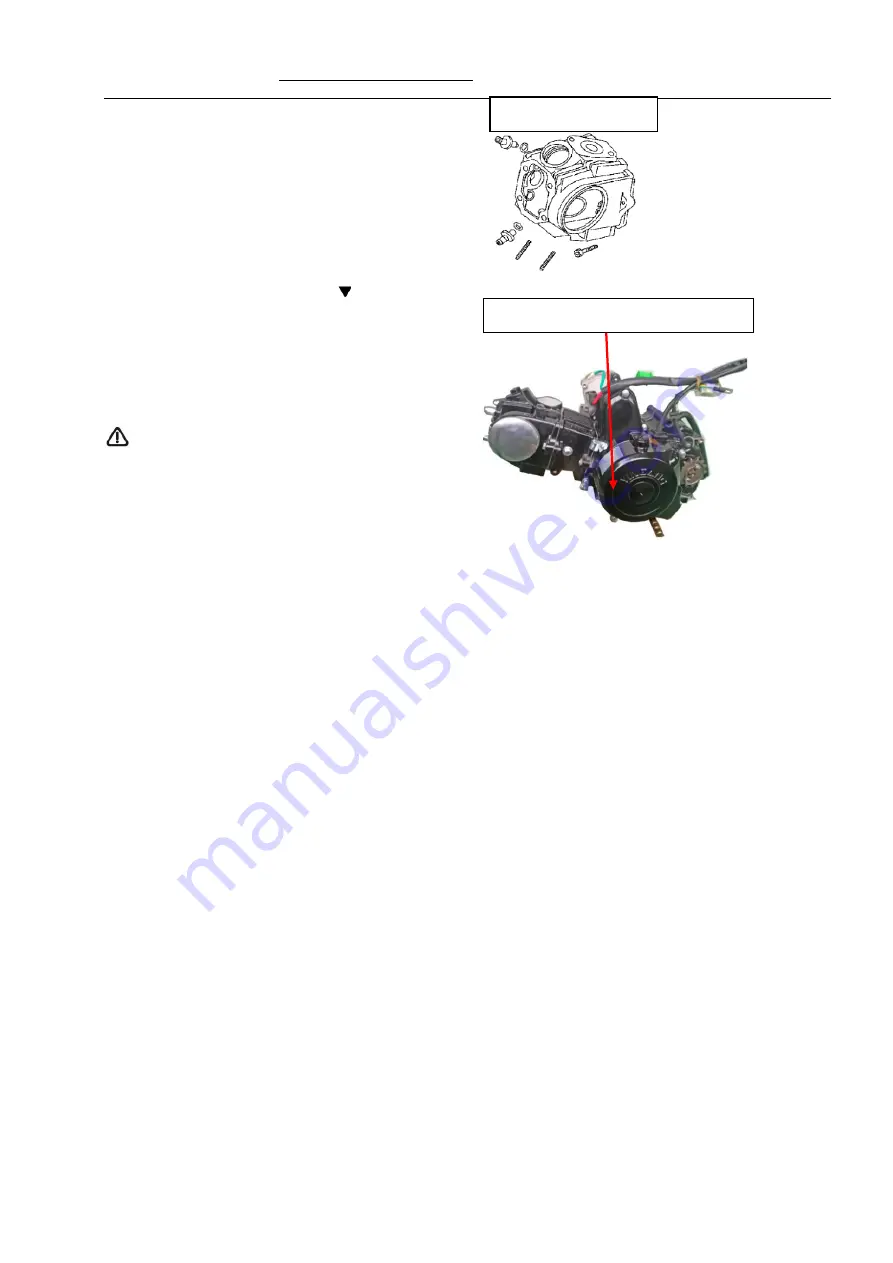

Adjustment of Ignition Time

That the ignition lead angle is not correct will cause a

series of problem that engine is difficult to start

,

power

decrease

,

oil consumption increase

,

engine overheats

,

burning is not complete

,

emission exceed standard

,

use

life reduce and so on

.

So should adjust the ignition lead

angle at first

Need not adjust the ignition timing if engine without

contact ignition

.

If the ignition system is abnormal

,

should

check electronic ignition

,

high-voltage coil

,

charging on

the generator and trigger coil etc.

.

After properly timing, pull off the tensioner locking key and

coat the mixture of engine oil and molybdenum disulfide

on the tensioner to make it tensioned; mount the sprocket

retaining plate and retaining bolt.

Cylinder pressure

When the engine fails to start or is difficult to start, or

when questioning the cylinder pressure is abnormal after

other possible faults have been excluded, check the

cylinder pressure.

Cylinder pressure:

≥0.8MPa/300r/min.

While testing, remove the spark plug and mount

apressure gauge at the position where the spark plug

ismounted; fully open the throttle bar and electronically

start the engine, and then check all connecting points of

the pressure gauge for gas leak. Zero the pressure gauge

and restart the engine until the pressure gauge reading

stops rising. The maximum reading of the pressure gauge

can usually be reached after 1 or 2 startups. Such

maximum reading shall be the cylinder pressure. Upon

completion of testing, mount the spark plug to its original

position.

The boss is in the center of the hole

While aligning

Содержание YG48Q-5A

Страница 38: ...YG48Q 5AMaintenance ManualFuel system 41 4 Fuel system...

Страница 42: ...YG48Q 5A Maintenance ManualRemoval and installation of engine 46 5 Removal and installation of engine...

Страница 92: ...YG48Q 5AMaintenance ManualFrame and exhaust system 105 10 Frame and exhaust system...

Страница 108: ...YG48Q 5A Maintenance ManualRear wheel and rear suspension device 121 12 Rear wheel and rear suspension device...

Страница 123: ...YG48Q 5A Maintenance ManualIllumination signal system 136 Circuit schematic drawing...

Страница 126: ...YG48Q 5A Maintenance ManualIllumination signal system 139...

Страница 133: ...YG48Q 5A Maintenance ManualEngine management system 146 Major parts and components...

Страница 134: ...YG48Q 5A Maintenance ManualEngine management system 147...

Страница 144: ...YG48Q 5A Maintenance ManualElectrical System Diagram 157 19 Electrical System Diagram...