6-16

183523-1CD

183523-1CD

6

Maintenance and Troubleshooting

6.12 Troubleshooting

RM2-755-RDR Postioner

6.12 Troubleshooting

6.12.1 Positioner

6.12.2 MotoMount

High duty cycles under heavy loads and/or dirty operating conditions may

cause the drive bushing to wear. This may be indicated by an increase in

the tooling position repeatability. Call Customer Support for details.

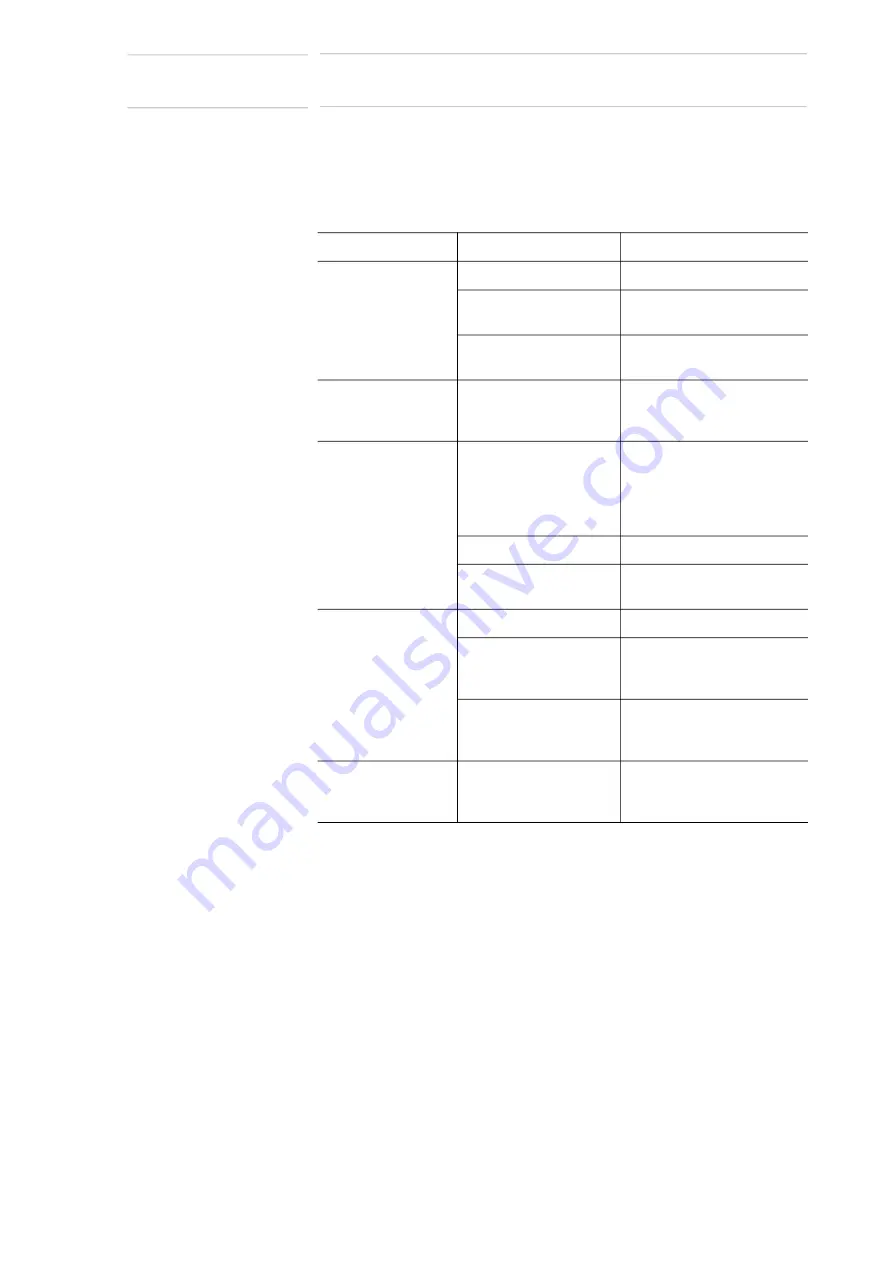

Table 6

-

4: Troubleshooting

Symptom

Probable Cause

Corrective Action

Motor does not start

Loose connection

Check all wire connections.

Incorrect wiring

Check that system has been

wired correctly.

Overload

Reduce load or reduce

unbalanced load.

Unstable operation

Incorrect wiring

Inspect and correct wiring

across motor terminals L1,

L2, L3, and PE.

Motor overheats

Excessive ambient

temperature

Reduce ambient

temperature below 40° C

(104° F). Positioner has an

operating range of 0 to 45°

C (32 to 113°F).

Motor surface is dirty

Clean motor surface.

Motor overloaded

Reduce load or unbalanced

load.

Unusual noise

Motor loosely mounted

Tighten mounting bolts.

Positioners misaligned

Realign Headstock/tailstock

(see

Noisy bearing

Check alignment, noise of

bearing, lubrication. Call

Customer Support.

Weld quality bad

Brushes misaligned

Remove brush(s) and

reinstall them properly.

Recheck as needed.

60 of 104