6-6

183523-1CD

183523-1CD

6

Maintenance and Troubleshooting

6.3 Grease Replenishment/Exchange for Speed Reducers

RM2-755-RDR Postioner

6.3.2 Tailstock Lubrication

The lubrication of the swingarm main axis bearing and the motomount

axis bearing are required to be lubricated monthly.

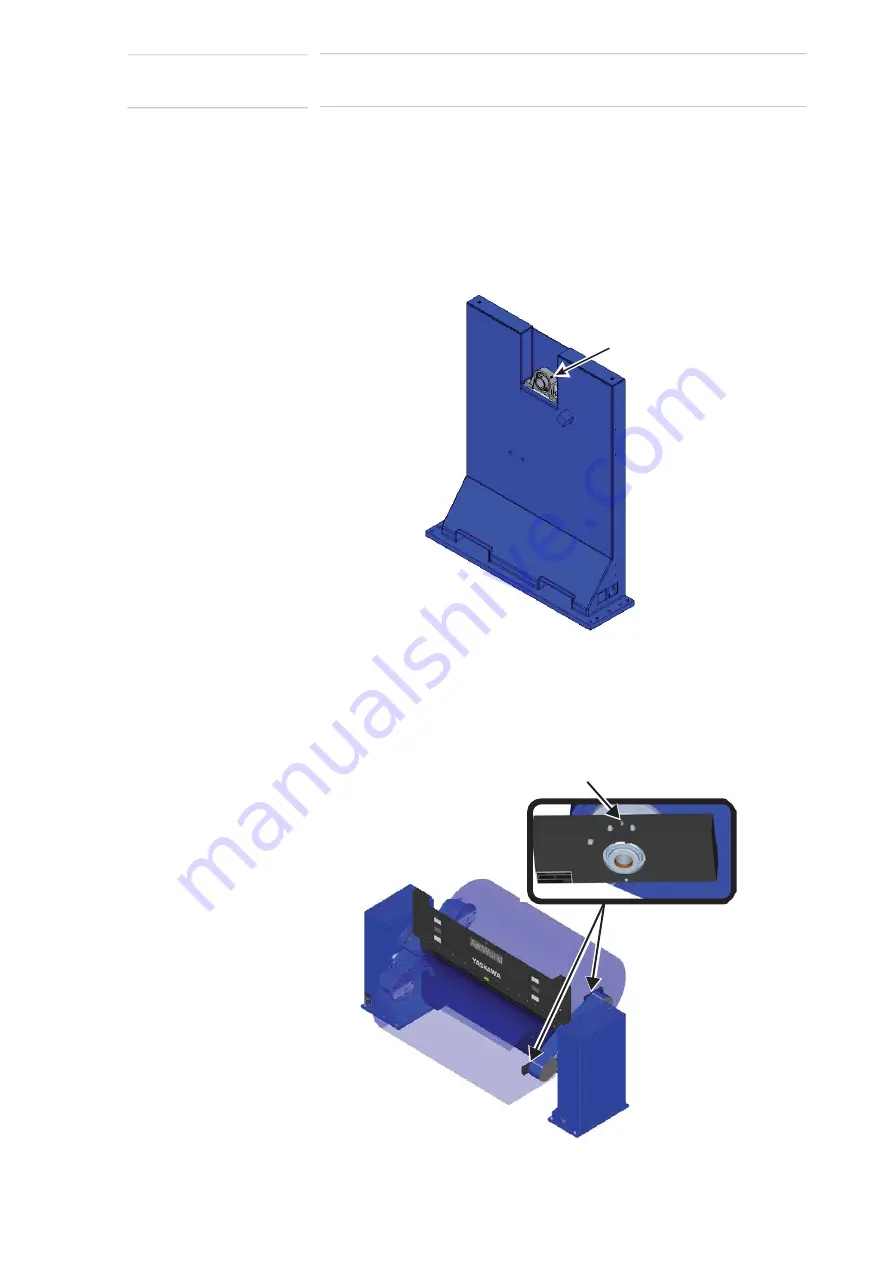

6.3.2.1 Swingarm Main Swing Axis

Apply Mobil CM-P grease to the grease fitting by using a standard grease

gun and pressing the lever 10 times (1.25 g x 10).

Fig. 6

-

3: Tailstock Main Axis Grease Fitting

6.3.2.2 Motomount Lubrication (If equipped)

Apply Mobil CM-P grease to each of grease fitting by squeezing the

grease gun lever five times (approximately 5 @ 1.25 g each).

See

for location of motomount grease fitting.

Fig. 6

-

4: Motomount Grease Fittings

TAILSTOCK SWINGARM

MAIN AXIS GREASE FITTING

GREASE FITTINGS

MOTOMOUNT

TAILSTOCK

50 of 104