3.2 Operating Procedures for Utility Functions

3.2.14 Manually Adjust Motor Current Detection Signal Offset (Fn00F)

3-35

3

Utility Function

s

3.2.14

Manually Adjust Motor Current Detection

Signal Offset (Fn00F)

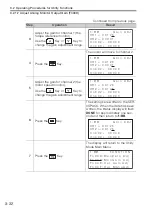

The adjustment that is made by this utility function is completed at the

factory. There is normally no reason to execute it.

Execute this utility function in the following cases.

•

If you think the torque ripple is abnormally large due to the current

detection signal offset

•

If you execute the Fn00E (Autotune Motor Current Detection Signal

Offset) utility function and the torque ripple is still large.

Observe the following precautions when you execute this utility function.

•

Do not couple the motor shaft to the machine (operate the motor with

no load) and operate the motor at 100 min

-1

.

•

Monitor the torque reference with the S or the analog moni-

tor and adjust the offset to minimize the torque ripple.

•

Adjust the offsets for the phase-U current and phase-V current of the

Servomotor so that they are balanced. Alternately adjust both offsets

several times.

Note: These offsets are not initialized even if you execute the Fn005 (Initialize Parame-

ters) utility function.

Preparations

Always check the following before you manually adjust the motor current

detection signal offset.

•

The parameters must not be write-prohibited (Fn010 must be set to

0000).