EN 34

YASKAWA Europe TOEP_C710606_97A - AC Drive A1000 IP54READY - Quick Start Guide

8 Safe Disable Input Function

8

Safe Disable Input Function

Specifications

Precautions

DANGER!

Improper use of the Safe Disable function can result in serious injury or even death.

Make sure the whole system or machinery that the Safe Disable function is used in complies with safety requirements. When

implementing the Safe Disable function into the safety system of a machine, a thorough risk assessment for the whole system has to

be carried out to assure it complies with relevant safety norms (e.g., ISO13849, IEC61508, EN/IEC62061,...).

DANGER!

When using a PM motor, even if the drive output is shut off by the Safe Disable function, a break down of two output

transistors can cause current to flow through the motor winding, resulting in a rotor movement for a maximum angle of 180 degree

(electrically). Make sure such a situation would have no effect on the safety of the application when using the Safe Disable function.

This is not a concern with induction motors.

DANGER!

The Safe Disable function can switch off the drive output, but does not cut the drive power supply and cannot electrically

isolate the drive output from the input. Always shut off the drive power supply when performing maintenance or installations on the

drive input side as well as the drive output side.

DANGER!

When using the Safe Disable inputs, make sure to remove the wire links between terminals H1, H2, and HC that were

installed prior to shipment. Failing to do so will keep the Safe Disable circuit from operating properly and can cause injury or even

death.

DANGER!

All safety features (including Safe Disable) should be inspected daily and periodically. If the system is not operating

normally, there is a risk of serious personal injury.

DANGER!

Only a qualified technician with a thorough understanding of the drive, the instruction manual, and safety standards should

be permitted to wire, inspect, and maintain the Safe Disable input.

NOTICE:

From the moment terminal inputs H1 and H2 have opened, it takes up to 1 ms for drive output to shut off completely. The

sequence set up to trigger terminals H1 and H2 should make sure that both terminals remain open for at least 1 ms in order to properly

interrupt drive output.

NOTICE:

The Safe Disable Monitor (output terminals DM+ and DM-) should not be used for any other purpose than to monitor the

Safe Disable status or to discover a malfunction in the Safe Disable inputs. The monitor output is not considered a safe output.

Using the Safe Disable Function

The Safe Disable inputs provide a stop function in compliance with “Safe Torque Off” as defined in the IEC61800-5-2.

Safe Disable inputs have been designed to meet the requirements of the ISO13849-1, Category 3 PLd, and IEC61508,

SIL2.

A Safe Disable Status Monitor for error detection in the safety circuit is also provided.

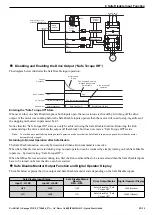

Safe Disable Circuit

The Safe Disable circuit consists of two independent input channels that can block the output transistors. In addition, it

provides a monitoring channel that indicates the status of those two input channels.

The input can either use the drive internal power supply or an external power supply. Use jumper S3 on the terminal

board to select between Sink or Source mode with either internal or external power supply.

A single photocoupler output is available to monitor the status of the Safe Disable terminals.

for signal specifications when using this output.

Inputs / Outputs

Two Safe Disable inputs and one EDM output according to ISO13849-1 Cat. 3 PLd,

IEC61508 SIL2.

Operation Time

Time from input open to drive output stop is less than 1 ms.

Failure Probability

Demand Rate Low

PFD = 5.15E

-5

Demand Rate High or

Continuous

PFH = 1.2E

-9

Performance Level

The Safe Disable feature satisfies all requirements of performance level d (PLd) as defined

by ISO13849-1 (this includes DC from EDM).