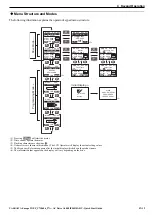

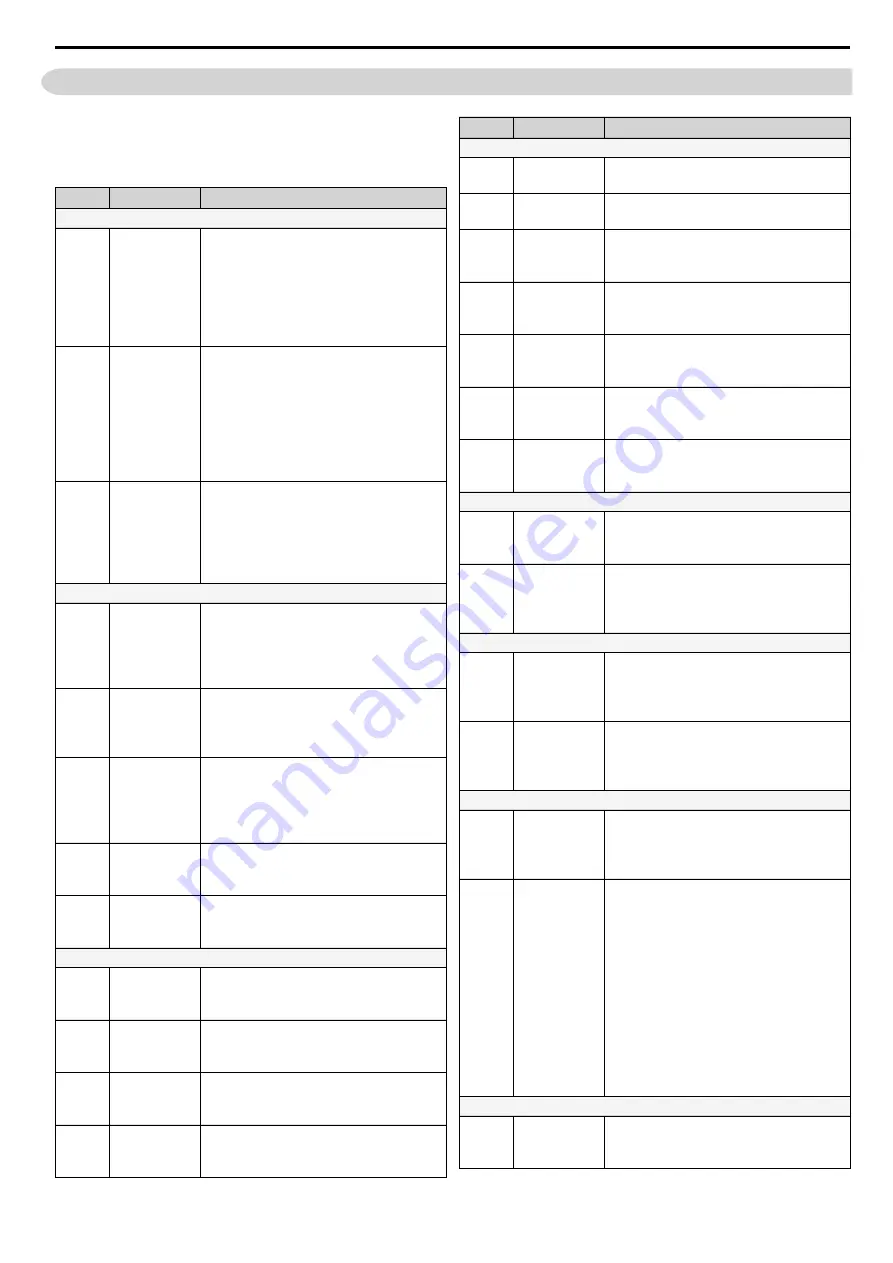

6 Parameter Table

YASKAWA Europe

TOEP_C710606_97A - AC Drive A1000 IP54READY - Quick Start Guide

EN 25

6

Parameter Table

This parameter table shows the most important parameters.

Default settings are bold type. Refer to the Technical

Manual for a complete list of parameters.

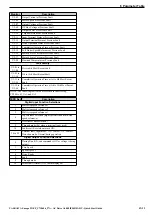

No.

Name

Description

Initialization Parameters

A1-01

Access Level

Selection

0: View and set A1-01 and A1-04. U

-

parameters can also be viewed.

1: User Parameters (access to a set of

parameters selected by the user, A2-01 to

A2-32)

2: Advanced Access (access to view and

set all parameters)

A1-02

Control

Method

Selection

0: V/f Control

1: V/f Control with PG

2: Open Loop Vector Control

3: Closed Loop Vector Control

5: Open Loop Vector Control for PM

6: Advanced Open Loop Vector Control for

PM

7: Closed Loop Vector Control for PM

A1-03

Initialize

Parameters

0: No initialization

1110: User Initialize (parameter values must

be stored using parameter o2-03)

2220: 2-wire initialization

3330: 3-wire initialization

5550: oPE04 error reset

Operation Mode Selection

b1-01

Frequency

Reference

Selection 1

0: Digital operator

1: Analog input terminals

2: MEMOBUS/Modbus communications

3: Option PCB

4: Pulse input (terminal RP)

b1-02

Run

Command

Selection 1

0: Digital operator

1: Digital input terminals

2: MEMOBUS/Modbus communications

3: Option PCB

b1-03

Stopping

Method

Selection

0: Ramp to stop

1: Coast to stop

2: DC Injection Braking to stop

3: Coast with timer

9: Simple Positioning Stop

b1-04

Reverse

Operation

Selection

0: Reverse enabled.

1: Reverse disabled.

b1-14

Phase Order

Selection

0: Standard

1: Switch phase order (reverses the direction

of the motor)

DC Injection Braking

b2-01

DC Injection

Braking Start

Frequency

Sets the frequency at which DC Injection

Braking starts when “Ramp to stop” (b1-03

= 0) is selected.

b2-02

DC Injection

Braking

Current

Sets the DC Injection Braking current as a

percentage of the drive rated current.

b2-03

DC Injection

Braking Time

at Start

Sets DC Injection Braking (Zero Speed

Control when in CLV/PM) time at start.

Disabled when set to 0.00 seconds.

b2-04

DC Injection

Braking Time

at Stop

Sets DC Injection Braking time at stop.

Acceleration/ Deceleration

C1-01

Acceleration

Time 1

Sets the time to accelerate from 0 to

maximum frequency.

C1-02

Deceleration

Time 1

Sets the time to decelerate from maximum

frequency to 0.

C1-03 to

C1-08

Acceleration/

Deceleration

Time 2 to 4

Set the accel/decel times 2 to 4 (set like C1-

01/02).

C2-01

S-Curve

Characteristic

at Accel Start

S-curve at acceleration start.

C2-02

S-Curve

Characteristic

at Accel End

S-curve at acceleration end.

C2-03

S-Curve

Characteristic

at Decel Start

S-curve at deceleration start.

C2-04

S-Curve

Characteristic

at Decel End

S-curve at deceleration end.

Slip Compensation

C3-01

Slip

Compensation

Gain

Sets the gain for the motor slip

compensation function used for motor 1.

C3-02

Slip

Compensation

Primary Delay

Time

Adjusts the slip compensation function

delay time used for motor 1.

Torque Compensation

C4-01

Torque

Compensation

Gain

Sets the gain for the automatic torque

(voltage) boost function and helps to

produce better starting torque. Used for

motor 1.

C4-02

Torque

Compensation

Primary Delay

Time

Sets the torque compensation filter time.

Carrier Frequency

C6-01

Drive Duty

Selection

0: Heavy Duty (HD) for constant torque

applications.

1: Normal Duty (ND) for variable torque

applications.

C6-02

Carrier

Frequency

Selection

1: 2.0 kHz

2: 5.0 kHz

3: 8.0 kHz

4: 10.0 kHz

5: 12.5 kHz

6: 15.0 kHz

7: Swing PWM1 (Audible sound 1)

8: Swing PWM2 (Audible sound 2)

9: Swing PWM3 (Audible sound 3)

A: Swing PWM4 (Audible sound 4)

B to E: No setting possible

F: User defined (determined by C6-03

through C6-05)

Frequency Reference

d1-01 to

d1-16

Frequency

Reference

1 to 16

Sets the frequency reference for the drive.

Setting units are determined by parameter

o1-03.

No.

Name

Description