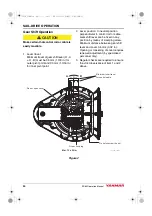

PRODUCT OVERVIEW

SD60 Operation Manual

11

NOTICE

The anode of the Sail-Drive is only

calculated for the Sail-Drive. Changing the

material of the propeller may require

additional anodes to be installed on the

Sail-Drive.

NOTICE

Failure to use the correct anode material

may result in inadequate protection and

excessive corrosion of underwater drive

system components. Use only aluminum

anodes in brackish and saltwater

applications. In freshwater applications,

use aluminum or magnesium anodes for

best results. Never use magnesium

anodes in brackish or salt water, as they

will deteriorate rapidly, which will lead to

severe damage to the drive system.

If sacrificial anodes erode quickly or if

signs of corrosion are evident, the owner

should take immediate corrective action.

Yanmar recommends consulting an

engineer specializing in marine electricity

and corrosion control to determine the best

way to correct the rapid erosion of the

anodes.

Electrical Connections and

Regulations According to

International Rules ISO

60092-507 IEC:2008

It is recommended to perform the boat

electric system in conformity with the

regulation ISO 60092-507 IEC 2008, or

equal local and international rules or laws.

To protect the boat from galvanic current

when it is connected to the power source

located on the dry land (wharf), it is

recommended to install on the boat a

galvanic isolator on the ground conductor

of the AC power line.

This will prevent the flow of galvanic

current with low voltage but will allow a

normal supply.

For more information about or to find

different solutions of the power system

from the dry land, refer to the instructions

of ABYC (American Boat and Yacht

Council) in chapter E-11 or ISO 60092-507

IEC 2008.

At the same purpose can also be used an

isolating transformer with the relevant

characteristics of the circuit. Even in this

case, refer to the applicable ABYC E-11 or

ISO 60092-507 IEC 2008 for more

information and suggestions.

Note: We advise you to install an isolating

transformer for the electrical power

supply from pier.

SHORE POWER

Vessels that are connected to shore power

require additional protection to prevent

destructive low voltage galvanic currents

from passing through the shore power

ground wire. Galvanic isolators are

available from the aftermarket (not

supplied by Yanmar) to block these

currents while still providing a path to

ground for dangerous shock currents.

NOTICE

If the AC shore power ground is not

isolated from the boat ground, sacrificial

anodes may be unable to neutralize the

increased galvanic potential. Corrosion

damage that results from the improper

system design or application is not

covered by the Yanmar Limited Warranty.

SD60_OPM.book 11 ページ 2017年12月8日 金曜日 午後3時6分

Содержание SD60

Страница 1: ...English en English OPERATION MANUAL SAIL DRIVE SD60...

Страница 6: ...INTRODUCTION 2 SD60 Operation Manual This Page Intentionally Left Blank SD60_OPM book 2...

Страница 18: ...PRODUCT OVERVIEW 14 SD60 Operation Manual This Page Intentionally Left Blank SD60_OPM book 14...

Страница 38: ...ELECTRIC INSTALLATION 34 SD60 Operation Manual This Page Intentionally Left Blank SD60_OPM book 34...

Страница 42: ...SPECIFICATIONS 38 SD60 Operation Manual This Page Intentionally Left Blank SD60_OPM book 38...

Страница 44: ...YANMAR CO LTD https www yanmar com 0ASDM EN0022 30 1 YTSK...