GENERAL SERVICE INFORMATION

3TNV88F Service Manual

4-7

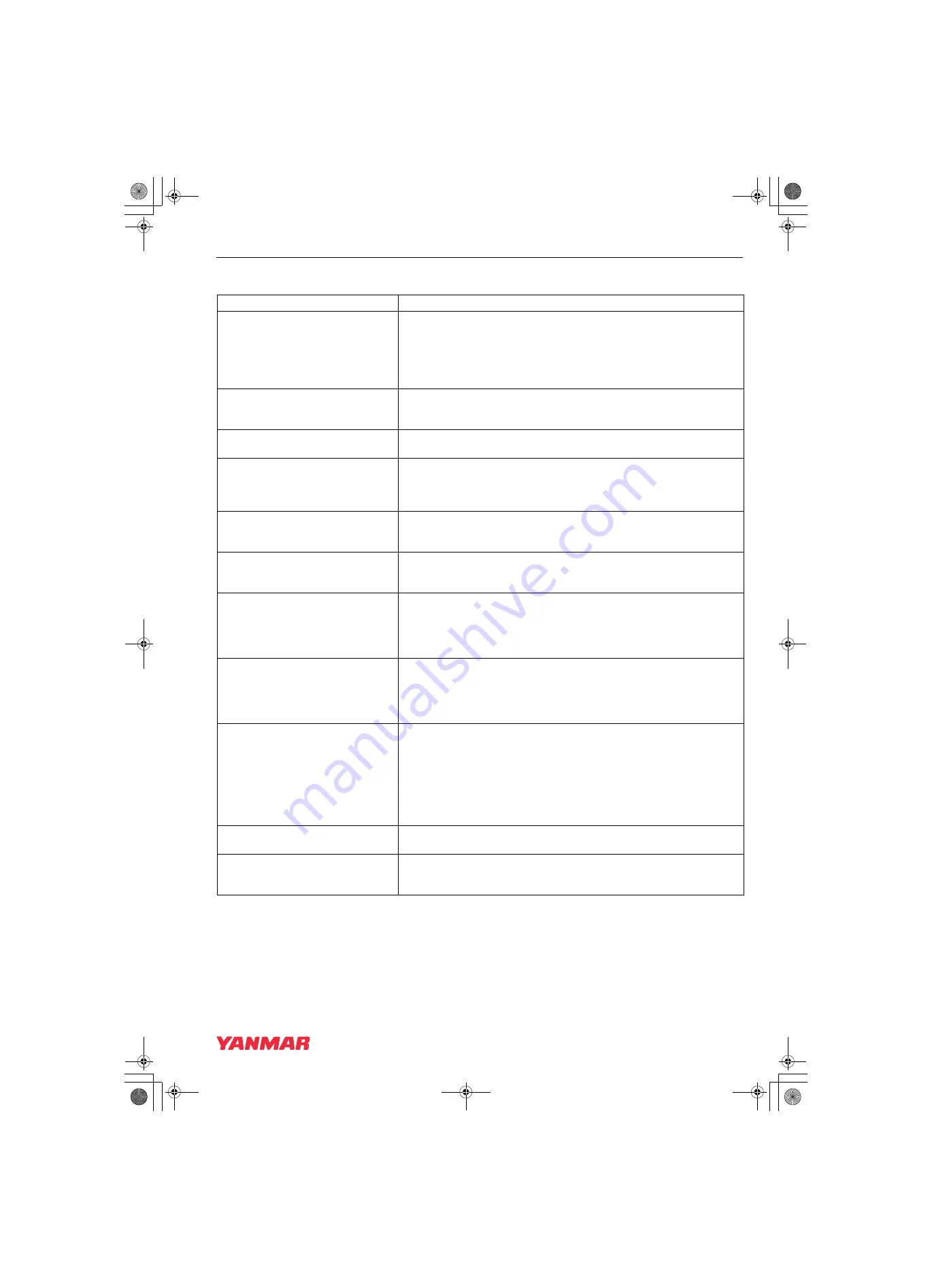

Function of Major Engine Components

FUNCTION OF MAJOR ENGINE COMPONENTS

Components

Functions

Air cleaner

The air cleaner prevents airborne contaminants from entering the engine.

Since the air cleaner is application specific, it must be carefully selected by

an application engineer. It is not part of the basic engine package as shipped

from the YANMAR factory. Periodic replacement of the air cleaner filter

element is necessary. See the

Periodic Maintenance Schedule on page 5-5

for the replacement frequency.

Alternator

The alternator is driven by a V-belt which is powered by the crankshaft V-

pulley. The alternator supplies electricity to the engine systems and charges

the battery while the engine is running.

Dipstick (engine oil)

The engine oil dipstick is used to determine the amount of engine oil in the

crankcase.

Electric fuel pump

The electric fuel pump makes sure there is a constant supply of diesel fuel

to the fuel injection pump. The electric fuel pump is electro-magnetic and

runs on 12 V DC. It must be installed on every application. This is standard

equipment with every engine.

Engine oil filter

The engine oil filter removes contaminants and sediments from the engine

oil. Periodic replacement of the engine oil filter is necessary. See the

Periodic Maintenance Schedule on page 5-5

for the replacement frequency.

Engine oil cooler

(if equipped)

The engine oil cooler helps to keep the engine oil cool. Engine coolant from

the cooling system is circulated through an adapter at the base of the engine

oil filter assembly and then returned to the coolant pump inlet.

Fuel filter

The fuel filter removes contaminants and sediments from the diesel fuel.

Periodic replacement of the fuel filter is necessary. See the

Maintenance Schedule on page 5-5

for the replacement frequency.

Please note that the word “diesel” is implied throughout this manual

when the word “fuel” is used.

Fuel filter/water separator

The fuel filter/water separator removes contaminants, sediments and water

from the diesel fuel going to the fuel filter. This is a required component of

the fuel system. This is standard equipment with every engine. The

separator is installed between the fuel tank and the electric fuel pump.

Periodically drain the water from the fuel filter/water separator.

Fuel tank

The fuel tank is a reservoir that holds diesel fuel. When the fuel leaves the

fuel tank it goes to the fuel filter/water separator. Next the fuel is pumped to

the fuel filter by the electric fuel pump. Then the fuel goes to the fuel injection

pump. Since the fuel is used to keep the fuel injection pump cool and

lubricated, more fuel than necessary enters the injection pump. When the

injection pump pressure reaches a preset value, a relief valve allows the

excess fuel to be returned back to the fuel tank. The fuel tank is a required

engine component.

Side and top filler port (engine oil)

You can fill the crankcase with engine oil from either the side or the top filler

port depending upon which one is most convenient.

Starter motor

The starter motor is powered by the battery. When you turn the key switch

in the operator’s console to the START position, the starter motor engages

with the ring gear installed on the flywheel and starts the flywheel in motion.

3TNV88F_SVM_A4.book 7 ページ 2012年7月26日 木曜日 午後6時4分