ELECTRICAL COMPONENTS

8-62

the standard charging current written on

the battery.

TIP

If the current is lower than the standard charging

current written on the battery, set the charging

voltage adjust dial at 20–24 V and monitor the

amperage for 3–5 minutes to check the battery.

d. Adjust the voltage so that the current is at

the standard charging level.

e. Set the time according to the charging

time suitable for the open-circuit voltage.

f. If charging requires more than 5 hours, it is

advisable to check the charging current af-

ter a lapse of 5 hours. If there is any

change in the amperage, readjust the volt-

age to obtain the standard charging cur-

rent.

g. Measure the battery open-circuit voltage

after leaving the battery unused for more

than 30 minutes.

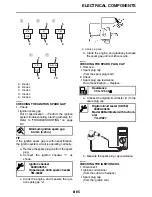

Charging method using a constant volt-

age charger

a. Measure the open-circuit voltage prior to

charging.

TIP

Voltage should be measured 30 minutes after

the engine is stopped.

b. Connect a charger and ammeter to the

battery and start charging.

c. Make sure that the current is higher than

the standard charging current written on

the battery.

TIP

If the current is lower than the standard charging

current written on the battery, this type of battery

charger cannot charge the VRLA (Valve Regu-

lated Lead Acid) battery. A variable voltage

charger is recommended.

d. Charge the battery until the battery’s

charging voltage is 15 V.

TIP

Set the charging time at 20 hours (maximum).

e. Measure the battery open-circuit voltage

after leaving the battery unused for more

than 30 minutes.

6. Install:

•

Battery

7. Connect:

•

Battery lead

(to the battery terminals)

NOTICE

ECA26980

First, connect the positive battery lead, and

then the negative battery lead.

8. Check:

•

Battery terminal

Dirt

Clean with a wire brush.

Loose connection

Connect properly.

9. Lubricate:

•

Battery terminal

10.Install:

•

Seat

•

Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-1.

EAM30292

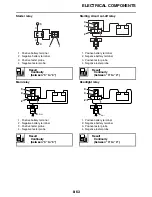

CHECKING THE RELAYS

Check each switch for continuity with the digital

circuit tester. If the continuity reading is incor-

rect, replace the relay.

1. Disconnect the relay from the wire harness.

2. Connect the digital circuit tester (

) and bat-

tery (12 V) to the relay terminal as shown.

Check the relay operation.

Out of specification

Replace.

•

Standard charging current is reached

Battery is good.

•

Standard charging current is not reached

Replace the battery.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

Recommended lubricant

Dielectric grease

Digital circuit tester (CD732)

90890-03243

Model 88 Multimeter with tachom-

eter

YU-A1927

Содержание WR250F 2022

Страница 5: ...EAM20093 YAMAHA MOTOR CORPORATION U S A WR MOTORCYCLE LIMITED WARRANTY...

Страница 8: ......

Страница 10: ......

Страница 41: ...MULTI FUNCTION DISPLAY 1 29...

Страница 62: ...ELECTRICAL SPECIFICATIONS 2 9 Radiator fan motor fuse 5 0 A Spare fuse 15 0 A...

Страница 70: ...CABLE ROUTING DIAGRAM 2 17 EAM20152 CABLE ROUTING DIAGRAM Frame and engine left side view...

Страница 72: ...CABLE ROUTING DIAGRAM 2 19 Frame and engine right side view...

Страница 74: ...CABLE ROUTING DIAGRAM 2 21 Handlebar front view...

Страница 76: ...CABLE ROUTING DIAGRAM 2 23 Frame and engine top view...

Страница 78: ...CABLE ROUTING DIAGRAM 2 25 Frame and battery top view...

Страница 80: ...CABLE ROUTING DIAGRAM 2 27 Rear brake right side view...

Страница 82: ...CABLE ROUTING DIAGRAM 2 29 Front brake front view and right side view...

Страница 84: ...CABLE ROUTING DIAGRAM 2 31 Taillight top view and right side view...

Страница 86: ...CABLE ROUTING DIAGRAM 2 33...

Страница 131: ...GENERAL CHASSIS 4 5 a Projection b Slot c Rib side cover d Rib rear fender a a a 1 1 c c b b d d...

Страница 201: ...CHECKING THE SHIFT DRUM ASSEMBLY 5 73 CHECKING THE TRANSMISSION 5 73 INSTALLING THE TRANSMISSION 5 74...

Страница 204: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 3 1 Oil filter element 2 Oil pump...

Страница 205: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 4 1 Intake camshaft 2 Exhaust camshaft...

Страница 206: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 5 1 Camshaft 2 Oil pressure check bolt 3 Oil pump 4 Oil filter element...

Страница 259: ...SHIFT SHAFT 5 58 TIP Align the punch mark a on the shift shaft with the punch mark b in the shift pedal 1 1 2 2 a b...

Страница 265: ...OIL PUMP 5 64 A Primary drive gear side B Crankcase cover side 5 7 mm 0 02 0 28 in 5 c d 6 8 b 8 6 7 E...

Страница 278: ...TRANSMISSION 5 77...

Страница 288: ...WATER PUMP 6 9...

Страница 298: ...THROTTLE BODY 7 9...

Страница 301: ......

Страница 302: ...IGNITION SYSTEM 8 1 EAM20142 IGNITION SYSTEM EAM30277 CIRCUIT DIAGRAM...

Страница 306: ...ELECTRIC STARTING SYSTEM 8 5 EAM20143 ELECTRIC STARTING SYSTEM EAM30279 CIRCUIT DIAGRAM...

Страница 312: ...CHARGING SYSTEM 8 11 EAM20144 CHARGING SYSTEM EAM30282 CIRCUIT DIAGRAM...

Страница 315: ...CHARGING SYSTEM 8 14...

Страница 316: ...SIGNALING SYSTEM 8 15 EAM20154 SIGNALING SYSTEM EAM30348 CIRCUIT DIAGRAM...

Страница 320: ...LIGHTING SYSTEM 8 19 EAM20153 LIGHTING SYSTEM EAM30346 CIRCUIT DIAGRAM...

Страница 323: ...LIGHTING SYSTEM 8 22...

Страница 324: ...COOLING SYSTEM 8 23 EAM20155 COOLING SYSTEM EAM30350 CIRCUIT DIAGRAM...

Страница 327: ...COOLING SYSTEM 8 26...

Страница 328: ...FUEL INJECTION SYSTEM 8 27 EAM20145 FUEL INJECTION SYSTEM EAM30284 CIRCUIT DIAGRAM...

Страница 353: ...FUEL INJECTION SYSTEM 8 52...

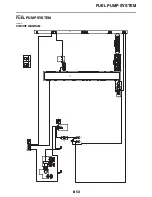

Страница 354: ...FUEL PUMP SYSTEM 8 53 EAM20146 FUEL PUMP SYSTEM EAM30287 CIRCUIT DIAGRAM...

Страница 388: ...SELF DIAGNOSTIC FUNCTION AND DIAGNOSTIC CODE TABLE 9 15...

Страница 398: ...CHASSIS 10 9...

Страница 400: ......

Страница 402: ......