For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

92/273

3.1.5.2. Multi Functional Nozzle Shutter

(1)

Various Sensors Adjustments

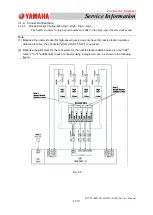

Nozzle Stocker Unit Lower Limit Sensor:

Confirm that the light is intercepted at the lower limit and the light is received in

moving up operation.

Nozzle Stocker Clamp Check Sensor:

Check that the light is intercepted when the nozzle stocker is set and that the light is

received when the nozzle stocker is removed.

Shutter Open/Close Sensor

:

Close Condition: Indicator Lamp: Red ON, Stability Indicator Lamp: Green ON

Open Condition: Indicator Lamp: Red OFF, Stability Indicator Lamp: Green ON

Nozzle Up-Status Detection Sensor

:

①

Sensor Optical Axis Adjustment

Set the nozzles in the stockers No. 1 and No. 9, and

adjust the sensor optical axis up and down on the

light emitting side and right, left, up and down on

the light receiving side. Fix the sensor where its

indication value becomes maximum (peaked).

*

Any indication values should be

"

125

"

or more.

②

Light Receiving Level Check

Set the nozzles in the stockers No. 1, No. 5 and No. 9.

(a) The light receiving level should be "480" or more without the nozzle risen.

(b) The light receiving level should be "100" or more when the nozzle is risen

0.8mm (as much as the thickness of flat washer).

(c) The light receiving level should be "0" or more when the nozzle is risen

1.3mm (as much as the total thickness of flat washers M2 + M5).

Fig. C15

Fig.C14

Set the multi-functional

nozzle also in the

stocker No. 5.

Nozzle Up-Status Detection

Sensor