For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

168/273

4.11.5. Operation Check

(1) Supply air and turn ON the power to start up the machine.

(2) After the start-up of the machine, perform the "All Zero" operation.

Select "Control" and "All Zero" in this order and press the [START] button in the "All

Zero" window.

(3) Select "Maint.", "Unit Adj.", "Nozzle Change" and "Nozzle Placement" in this order

and press the [START] button in the "Nozzle Placement" window to attach the nozzle

on the head.

* Basically, the nozzle placement operation is performed with the original data.

* After selecting the "Nozzle Placement" window, the [START] button should be

pressed within 10 seconds.

If the button is pressed more than 10 seconds later the status is cleared. In such a

case, repeat the procedure.

(4) Perform the "Nozzle Level Teaching" for the head for which the cleaning and

lubricating have been completed.

Select "Ship Adj.", "Noz Lv/Pos" and "Select Head" in this order and select the subject

head in the "Select Head" window. Then, select "Nozzle Level" and "Teach Start" in

this order and press the [START] button in the Teach Start" window.

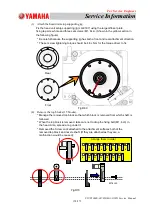

Compare the parameters in "Before" and "After" sections and confirm that the

difference is within

0.02 mm for all the nozzles.

(5) When the difference is within

0.02 mm, press the [Save] button to save the data.

Also, perform the "Nozzle Position Teaching" and save the data.

Fig.D83

Data Before Cleaning

Data After the Cleaning