26

assembly. Both edges of each blade must be grounded on front at 30° angle

and on the back 5° angle over 2mm to ensure correct clearances (Figure 13).

Anvil:

For the anvil, change side when the side edge on the tapered top gets blunt.

Change the anvil when both sides are blunt to ensure performance of the

chipper. Remember to readjust the anvil to a clearance of 0.5~1mm.

7.3.5 LUBRICATING GREASE

It is recommended to grease the rotor bearings daily before use. Use a high

temperature EP2 lithium complex grease.

7.3.6 WHEEL TYRE

Check the tyres regularly. Inflate the tube if necessary.(tyre pressure 1.5 bar

min., 1.9 bar max.)

7.4 PERIODIC MAINTENANCE

Perform regular inspections of the machine in order to ensure effective

operation of the machine and to prevent risk of injury to machine and user.

Figure 13.

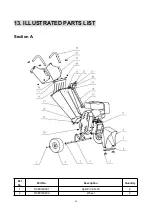

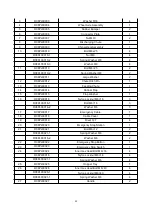

Содержание JONCO Series

Страница 2: ......

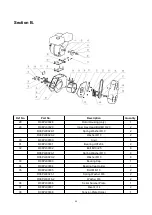

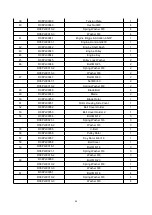

Страница 38: ...35 Section C Ref No Part No Description Quantity 62 R08PL00062 Catcher 1...

Страница 39: ...36...