Servicing and Maintenance

Servicing and Maintenance

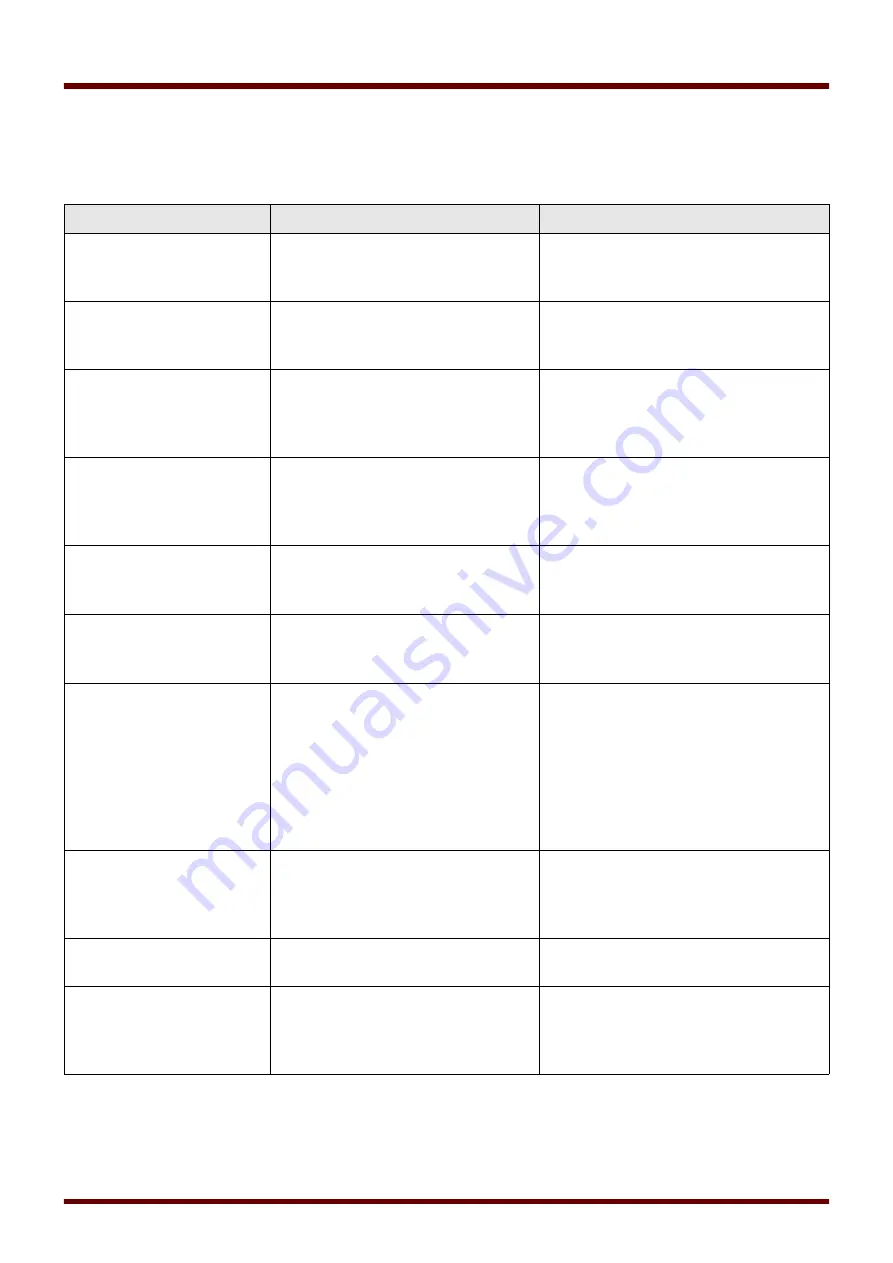

Within the scope of servicing and maintenance following checks of the unit hardware have to be conducted:

Component

Step

Interval/How often?

Output Relays

Please check the Output Relays via

Test menu Force/Disarm

(please see chapter Service)

Every 1

‒

4 years, depending on ambient

conditions.

Digital Inputs

Please supply a voltage to the Digital

Inputs and control if the appropriate

status signal appears.

Every 1

‒

4 years, depending on ambient

conditions.

Current plugs and Current

measurements

Please supply testing current to the

Current measurement inputs and

control the displayed measure values

from the unit.

Every 1

‒

4 years, depending on ambient

conditions.

Voltage plugs and Voltage

measurements

Please supply testing current to the

Voltage measurement inputs and

control the displayed measure values

from the unit.

Every 1

‒

4 years, depending on ambient

conditions.

Analog Inputs

Please feed analog signals into the

measurement inputs and check

if the

displayed measure values match.

Every 1

‒

4 years, depending on ambient

conditions.

Analog Outputs

Please check the Analog Outputs via

Test menu Force/Disarm

(please see chapter Service)

Every 1

‒

4 years, depending on ambient

conditions.

Battery

The device checks the battery as part

of its Self-Supervision, therefore no

dedicated testing activities are

required. If the battery is low, the

System LED flashes red/green, and an

error code is generated (see

Troubleshooting Guide).

In general the battery lasts more than

10 years.

Exchange by manufacturer.

Notice: The battery serves as buffering of the clock

(real time clock). There's no impact on the

functionality of the device if the battery breaks down,

except for the buffering of the clock while the unit is

in de-energized condition.

Self-monitoring contact

Switch of the auxiliary supply of the

unit. The Self-monitoring contact has

to dropout now. Please switch on the

auxiliary supply again.

Every 1

‒

4 years, depending on ambient

conditions.

Mechanical mounting of the

unit of the cabinet door

Check the torque related to the

specification of the Installation chapter.

With each maintenance or yearly.

Torque of all cable

connections

Check the torque related to the

specification of the Installation chapter

which describes the hardware

modules.

With each maintenance or yearly.

We recommend to execute an protection test after each 4 years period. This period can be extended to 6 years if a

function test is executed at least every 3 years.

1149

MCDLV4

DOK-HB-MCDLV4-2E

Содержание HighPROtec MCDLV4

Страница 1: ...Manual Line Differential Protection MCDLV4 Software Version 3 4 a DOK HB MCDLV4 2E Revision A English...

Страница 3: ...Order Code Order Code 3 MCDLV4 DOK HB MCDLV4 2E...

Страница 47: ...Installation and Connection 47 MCDLV4 DOK HB MCDLV4 2E...

Страница 164: ...Input Output and LED Settings 164 MCDLV4 DOK HB MCDLV4 2E...

Страница 433: ...Parameters 433 MCDLV4 DOK HB MCDLV4 2E...

Страница 457: ...Device Parameters 457 MCDLV4 DOK HB MCDLV4 2E...

Страница 473: ...Blockings 473 MCDLV4 DOK HB MCDLV4 2E...

Страница 822: ...Protective Elements Name Description Profibus Scada Cmd 16 Scada Command 822 MCDLV4 DOK HB MCDLV4 2E...

Страница 988: ...Protective Elements 988 MCDLV4 DOK HB MCDLV4 2E P P Q P Q P Q Q Q P S S...

Страница 989: ...Protective Elements 989 MCDLV4 DOK HB MCDLV4 2E Pr Q P Q P Qr...

Страница 1023: ...Protective Elements 1023 MCDLV4 DOK HB MCDLV4 2E...

Страница 1070: ...Supervision 1070 MCDLV4 DOK HB MCDLV4 2E...