Maintenance

Alternator Belt

2

2-6

doc110909

Maintenance

2.5

Alternator Belt

The belt tension should be checked after the first 100 hours of operation, when the bat-

tery is not charging properly or when the alternator belt is squealing. If the battery contin-

ues to not charge properly or the belt continues to squeal after the initial belt adjustment,

replace the belt.

1.

Release the blade tension and remove the blade from the sawmill if necessary. Turn the

key switch to OFF (0) and remove the key.

2.

Remove the drive belt cover and alternator cover.

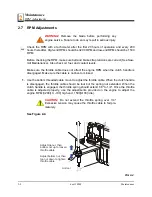

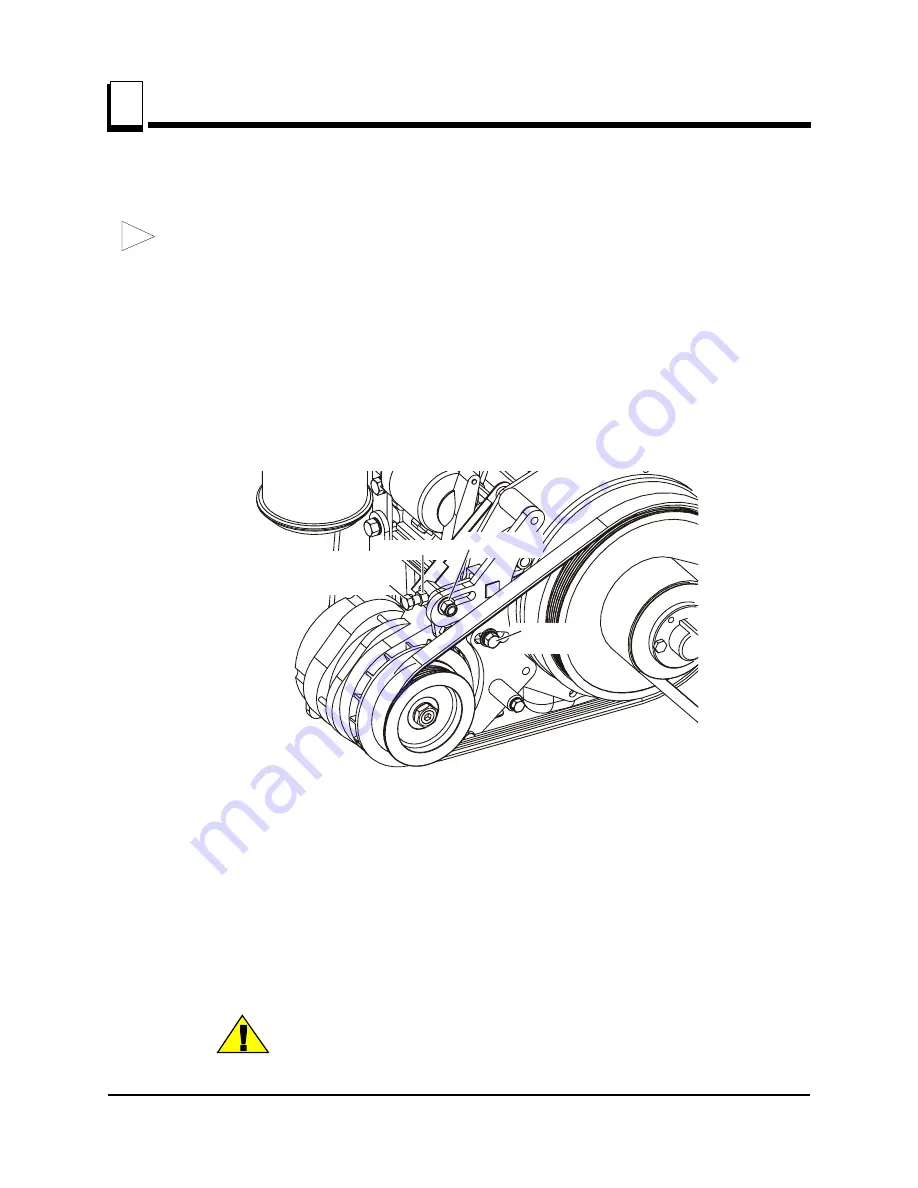

See Figure 2-2.

3.

Use a belt tension gauge to measure the belt tension. Place the gauge on the belt at the

midpoint between the two pulleys. If the belt tension is less than 3/16” with 9 lb. of deflec-

tion, tighten the belt as described below.

4.

Loosen the upper pivot, lower pivot and the adjustment bolt jam nut.

5.

Turn the belt tension adjustment bolt clockwise to tighten the belt, counterclockwise to

loosen the belt. Adjust the bolt until the proper belt tension is achieved.

CAUTION!

Do not overtighten the alternator belt. Damage

to the alternator will occur.

FIG. 2-2

AR

Belt Adjustment

Bolt

Jam Nut

Upper Pivot

Lower

Pivot

3H0748-11