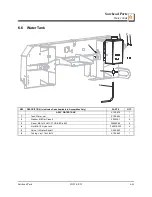

Sawmill Operation

Water Lube Operation

4-52

LX25 4/8/21

Sawmill Operation

4

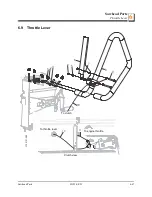

4.11 Water Lube Operation

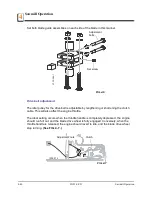

The Water Lube System keeps the blade clean. Water flows from a 1-gallon (3.79 liter)

bottle through a hose to the blade guide where the blade enters the log. A valve in the

bottle cap controls the amount of water flow.

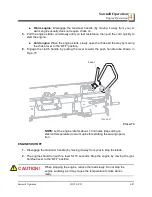

Not all types of wood require the use of the Water Lube System. When it is needed, use

just enough water to keep the blade clean. This saves water, and lowers the risk of stain

-

ing the boards with water.

When changing blades, let the blade spin with water running on it for about 15 seconds

before removing it. This will clean the blade of sap buildup. Dry blade with a rag before

storing or sharpening.

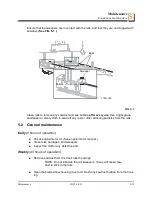

For lubrication benefits, add 12oz. (0.35L) of Lube Additive (part number

ADD-1

) to 5 gal

-

lons (18.9 liters) of water. Lube Additive enables some previously impossible timbers to

be cut by significantly reducing resin buildup on the blade. It helps to reduce heat buildup,

wavy cuts, and blade noise. This biodegradable and environmentally friendly pre-mix

includes a water softener additive, so it works with hard water.

Do not use flammable fuels or liquids such as diesel fuel. Failure

to follow this can damage the equipment and may result in serious

injury or death.

Use ONLY water and Lube Additive with the water lube accessory.

If these types of liquids are necessary to clean the blade, remove it

and clean with a rag.

If you are sawing in freezing temperatures, remove the water lube bottle from the sawmill

when done sawing and store it in a warm place. Blow any remaining water from the water

lube hose.

FIG. 4-16

TDLX25-09

WARNING!