Sawmill Setup

Tensioning The Blade

Sawmill Setup

60HD-R04doc112210

3-31

3

3.4

Tensioning The Blade

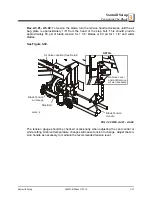

See Figure 3-28.

Before tensioning the blade, check the air pressure gauge to see that

the air tension system is properly charged. With the blade tension completely released

and the air bag plate against the stop bolt, the gauge should read 58 psi for 1 1/4” blades

or 78 psi for 1 1/2” and wider blades. To add air pressure, remove the air valve stem cover

and attach an air pump to the air valve. Add air until the gauge indicates the proper air

pressure. To release air, push in the valve stem. Replace the air valve stem cover when

finished adjusting the air pressure.

Rev. A9.00+:

Adjust the valve handle to the closed (down) position. Install the tensioner

handle to the tensioner and pump the lever until the air bag plate is approximately 1/8"

from the stop plate. Remove the tensioner handle and place in the storage position on the

tensioner assembly.

To release blade tension, adjust the valve handle to the open (up) position. Place the ten-

sioner handle between the end of the piston housing and bracket and pry the assembly

forward until the blade can be removed.

Rev. A5.03 - A8.01:

To tension the blade, push the blade tension handle up. Make sure

the handle lock flips to the locked (down) position after the blade tension is engaged.

WARNING!

Use both hands to operate the blade tensioner

handle. Be sure the handle lock engages (flips down) after

FIG. 3-28 (REV. A9.00+)

Valve Handle

Tensioner

Handle

Tensioner Handle

in Storage Position

600239-4B

Open Valve to

Release Blade

Tension

Stop Plate

Use tensioner handle

to pry piston housing

forward until blade

can be removed