Troubleshooting Guide

Electrical Problems

6

6-3

50HD07doc072310

Troubleshooting Guide

6.2

Electrical Problems

WARNING!

Before performing service near moving parts

such as blades, pulleys, motors, belts and chains, first turn

the key switch to the OFF (#0) position and remove the key.

If the key is turned on and moving parts activated, serious

injury may result.

WARNING!

Disconnect and lockout power before perform-

ing any service to the electrical system. For battery-pow-

ered equipment, disconnect the negative battery terminal

cable. Failure to do so may result in injury and/or electrical

system damage.

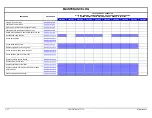

PROBLEM

CAUSE

SOLUTION

Up/down Excessively Slow.

Up/down belt loose.

Adjust belt to be as loose as possible

without slipping.

Vertical wear pads too tight.

Adjust pads.

Worn up/down motor or motor

brushes.

Replace up/down motor or motor

brushes.

Up/down Or Power Feed

Motors Do Not Work.

Worn/dirty contacts in drum

switch.

Replace switch or remove control panel

cover and clean contacts.

Bad key switch.

Replace key switch.

Circuit breaker.

Reset breaker in control box (

).

Burned-out motor.

Replace motor.

Bad connection on battery

post or loose wire.

Check for loose wire or terminal connec-

tions.

Power Feed Motor Does Not

Work.

Sawdust buildup in the power

feed pulleys.

Sawdust buildup puts mechanical bind

on power feed which causes automatic

motor protection circuit to activate.

Remove sawdust from pulleys and oper-

ate normally. If motor does not operate

after sawdust removal, reset circuit

breaker on the front of the control box.

Up/Down Or Power Feed

Switches Remain Engaged

When Switch Is Released.

Worn or dirty contacts in drum

switch.

Manually move the power feed or

up/down switch back to neutral or "off"

position. Replace drum switch or remove

control panel cover and clean and lubri-

cate contacts NOTE: Use only contact

grease supplied by Wood-Mizer.

Drum switch spring broken.

Manually move the power feed or

up/down switch back to neutral or "off"

position. Replace drum switch spring.