8

Electric Chute-Rotation Switch

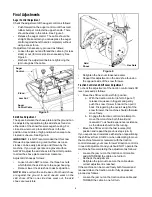

The electric chute-rotation switch is located on the left

side of the snow thrower dash panel. See Figure 7.

To change the direction in which discharged snow is

thrown, proceed as follows:

•

Push the toggle switch to the left to rotate the chute

counterclockwise.

•

Push the toggle switch to the right to rotate the

chute clockwise.

IMPORTANT:

Release the switch once the chute has

completed its rotation cycle in either direction. Failure to

do so can result in damage to the electric chute motor

and/or its drive gear.

Wheel Steering Controls

The left and right wheel steering controls are located on

the underside of the handles and are used to assist in

steering the snow thrower. Squeeze the right wheel

steering control when turning right, squeeze the left

control when turning left. Operate your snow thrower in

open areas until you become familiar with these

controls. See Figure 7.

NOTE: It is easier to maneuver a non-running snow

thrower with both wheel steering controls held in

simultaneously.

Headlight

The headlight is on whenever the engine is running.

Throttle Control

The throttle control is located on the engine. It regulates

the speed of the engine and will shut off the engine

when pushed down completely. See Figure 7.

Safety Ignition Key

The safety ignition key must be fully inserted in the

switch before the unit will start. Remove the ignition key

when the snow thrower is not in use. See Figure 7.

IMPORTANT:

Do NOT attempt to turn the key.

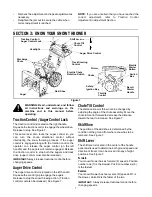

SECTION 4: OPERATING YOUR SNOW THROWER

Before Starting

WARNING: Read, understand, and follow

all instructions and warnings on the

machine and in this manual before

operating.

Gas And Oil Fill-up

Service the engine with gasoline and oil as

instructed in the separate engine manual packed with

your snow thrower. Read instructions carefully.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes an other sources

of ignition.

•

A plastic cup is provided inside the fuel fill opening

on the fuel tank. Remove and discard this cup

before filling up the tank. Use the separate fuel tank

cap to close after fill-up.

To Start Engine

NOTE: If unit shows any sign of motion (drive or

augers) with the clutch grips disengaged, shut engine

off immediately. Readjust as instructed in the Final

Adjustments in the Assembly Section.

•

Attach spark plug wire to spark plug. Make certain

the metal loop on end of the spark plug wire (inside

the boot) is fastened securely over the metal tip on

the spark plug.

•

Make certain the auger and drive clutch levers are

in the disengaged (released) position.

•

Move throttle control up to FAST position. Insert

ignition key into slot. See Figure 7. Be certain it

snaps into place. Do not turn key.

NOTE: Engine will not start unless ignition key is

inserted into ignition slot in carburetor cover.

Electric Starter

WARNING: The electric starter is

equipped with a grounded three-wire

power cord and plug and is designed to

operate on 120 volt AC household

current. It must be used with a properly

grounded three-prong receptacle at all

times to avoid the possibility of electric

shock. Follow all instructions carefully

prior to operating the electric starter.

•

Determine that your house wiring is a three-wire

grounded system. Ask a licensed electrician if you

are not certain.

•

If your house wiring system is not a three-wire

grounded system, do not use this electric starter

under any conditions.