7

ASSEMBLY

Note: You may now roll or drive your tractor off the skid.

Follow the ap pro pri ate instruction below to remove the

tractor from the skid

.

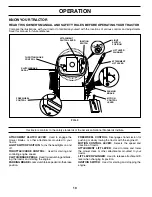

TO ROLL TRACTOR OFF SKID (See Op-

er a tion section for location and function of

con trols)

• Press lift lever plunger and raise attachment lift lever

to its highest po si tion.

• Release parking brake by de press ing clutch/brake

ped al.

• Place freewheel control in "trans mis sion dis en gaged

position" (See “TO TRANS

PORT” in the Op

er a tion

section of this manual).

• Roll tractor forward off skid.

• Remove banding holding the defl ector shield up against

tractor.

TO DRIVE TRAC

TOR OFF SKID (See Op-

er a tion section for location and function of

con trols)

WARNING:

Before start ing, read, un der stand and fol low

all in struc tions in the Op er a tion section of this man u al. Be

sure tractor is in a well-ventilated area. Be sure the area in

front of tractor is clear of other peo ple and objects.

• Be sure all the above assembly steps have been com-

pleted.

• Check engine oil level and fi ll fuel tank with gasoline.

• Place freewheel control in "trans mis sion en

gaged"

po si tion (see "TO TRANSPORT" in Op er a tion section

of this manual).

• Sit on seat in operating position, depress clutch/brake

pedal and set the parking brake.

• Place motion control lever in neutral (N) position.

• Press lift lever plunger and raise attachment lift lever

to its highest position.

• Start the engine. After engine has started, move throttle

control to idle position.

• Release parking brake.

• Slowly move the mo tion control lever for ward and slowly

drive tractor off skid.

• Apply brake to stop trac tor, set park ing brake and place

motion con trol lever in neutral po si tion.

• Turn ignition key to "STOP" position.

Continue with the in struc tions that follow.

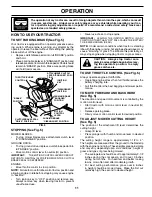

FIG. 2

ADJUSTMENT

BOLT

LOCK WASHER

02466

02465

SEAT PAN

SHOULDER

BOLT

FLAT WASHER

SEAT

FIG. 3

CHECK BATTERY (See Fig. 3)

• Lift seat pan to raised position.

• If this battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

(See "BATTERY" in MAINTENANCE section of this

manual for charging instructions).

SEAT PAN

LABEL

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment bolt securely.