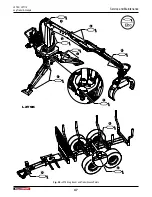

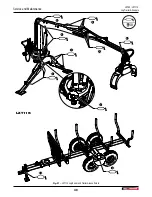

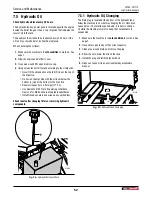

7.2 Grease Points

Use the table below and the following illustrations to locate

grease points on the log boom, trailer, and grapple.

Look for this decal on your machine. It

indicates a grease point and the interval in

hours.

1.

Use a hand-held grease gun. Wipe grease fitting with a

clean cloth before greasing to avoid injecting dirt and grit.

2.

Replace and repair broken fittings immediately.

3.

If fitting does not take grease, remove and clean thoroughly.

Also, clean lubricant passageway. Replace fitting if

necessary.

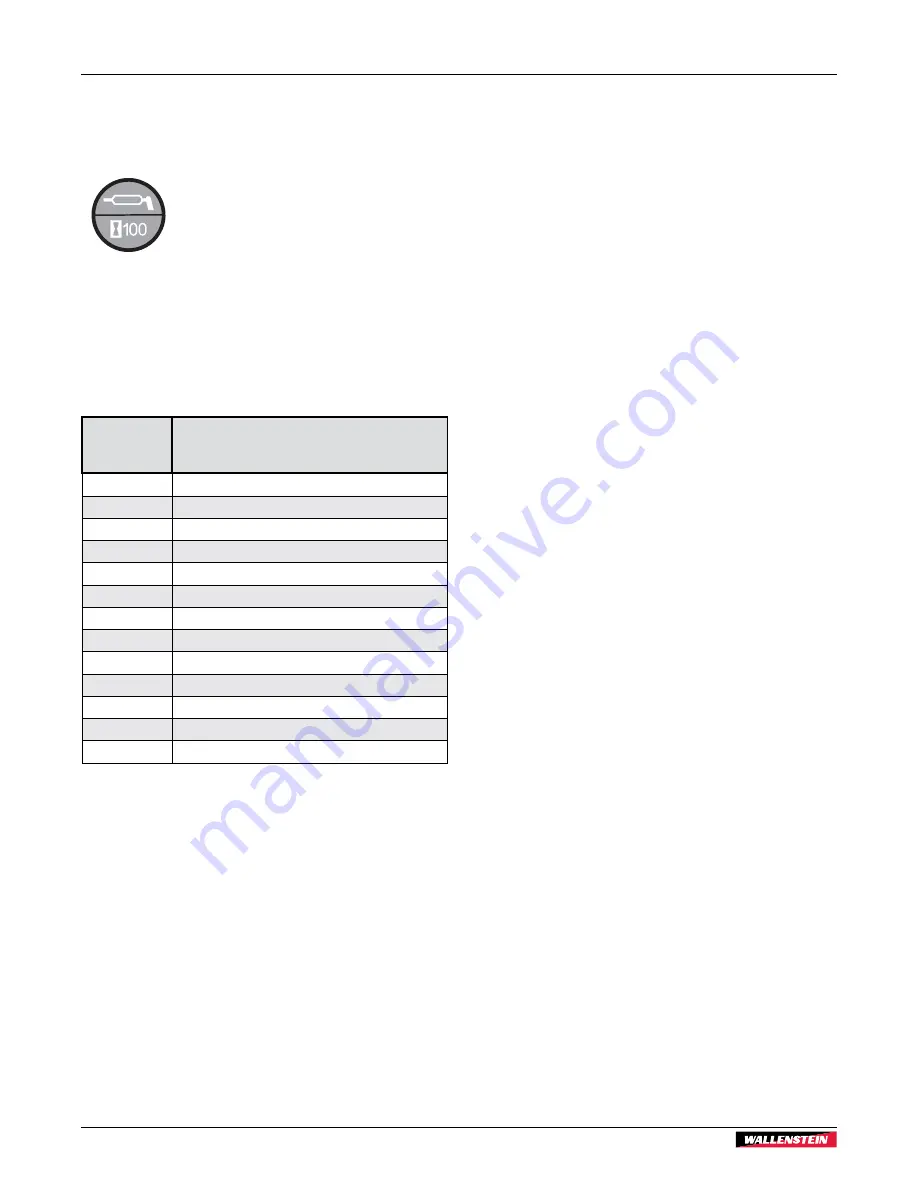

Location

Every 50 hours of operation

1

Stabilizer and stabilizer cylinder

2

Main Boom Hoist Cylinder

3

Main Boom Pivot

4

Dipper Cylinder

5

Dipper Cylinder Links

6

Boom Nose

7

Slew Assembly Ring Gear

8

Adjustable Tandem Slide

9

Tandem Axle Rocker–one fitting per side

10

Clevis hitch

11

Rotator

12

Grapple

13

Winch Drive (Option)

Service and Maintenance

LXT95 / LXT115

Log Trailer & Grapple

46

Содержание LXT115

Страница 64: ...www wallensteinequipment com ...