26

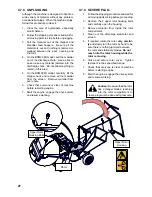

4�7�6 MOVING

The BXMC34S and the BXMC34B are designed

to be moved easily by tilting the chipper back on

its wheels using the hand-holds in the shredder

intake chute.

Tilt the unit back, then pull the unit to the desired

location. Ensure the engine is off and the clutch

lock is engaged before moving.

On the BXMC34S model, the wood mulch is

directed into the discharge cage under the

motor, and the unit must be moved periodically

to prevent plugging as the chips build up.

The BXMC34B uses a mulch collector bag and

does not require periodic moving.

Attaching \

Removing

Collector

Bag

Strap

Zipper Bottom

4�7�7 COLLECTOR BAG

(optional)

The BXMC34B model is designed with a discharge

chute that can be used with the optional mulch

collector bag (#Z99006). The mulch bag holds 2.7

cu.ft (28 litres) and is a mildew resistant synthetic

material. It is a porous material, allowing air

from the rotor to pass through without restricting

collection of the mulch.

•

Lift the spring loaded deflector, and slip the

collector bag over the end of the discharge

chute.

•

Use the strap on the end of the bag to attach

and secure it to the chute.

•

When full, loosen the strap, remove the bag from

the chute and take it to the mulch area.

•

Unzip the bottom of the bag and spread the

chips and mulch over the desired area.

•

Zip up the end of the bag and re-attach it to the

discharge cute.

No Bag:

The BXMC34B model can be used with or

without its collector bag. Be sure that the

deflector is down, so that the mulch will be

directed to the ground. Position the chipper

at the work site to allow room for the mulched

material to be accessible

Hand Holds

BXMC34S

Discharge Cage

Deflector

BXMC34B

Discharge Chute